Actually, I drove quite a ways to get it, but it is home and being cleaned up for use.

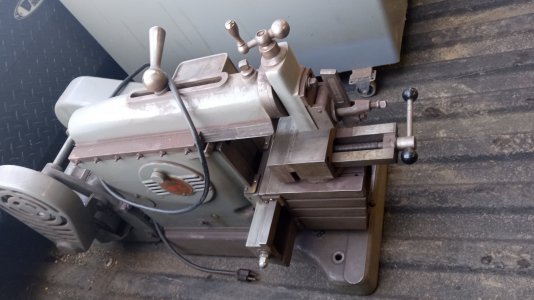

This unit looked like it had very little use, but it was terribly dirty. Sat uncovered for years. I could tell it was the newer style with the wide front base and the internal oil system. The old oil was clear enough I could see through it to the bottom of the sump. Where I wiped the dirt off the ways, there were no score marks, so the deal was made.

First step was to fix the feet on the cabinet. I added a 3" riser and some roller/feet units. Now I can move it around the shop to work on it.

After watching some videos and downloading the documents that were available it was time to tear into it. Started with some solvent and a brush at the top and worked my way down. Found the serial number. It is 00005S ! That seems really low. Could this be the fifth unit made after the change to the wide base and oil pump system?

Really was a struggle to get my hand inside the sump and loosen the set screw on the bottom of the rocker. It had a square head and was quite tight. Once the ram was off and the ways cleaned, most of the flaking was still there. Good news. Drained the sump and got fresh oil in it. The pump worked fine and once everything was cleaned, de-burred and put back together, I was able to run it and confirm the oil circulation before continuing.

Today I am cleaning and de-rusting the vise and the table.

Several things that don't seem right to my eye. There are some parts that have paint on them that probably shouldn't. To me this says a repaint, but the bulk of it does appear to be factory paint. Perhaps there was some sloppy touch up done by someone in the past. The lead screw on the down feed assembly was boogered up by some mook. The nut on the end of the handle was gone as were the threads on the end of the shaft. It looks like the shaft was welded back together but poorly done and the handle had been drilled and tapped for a set screw to hold it to the shaft. Of course that buggered up the shaft. And the shaft/screw assembly was bent.

Managed to get it straight enough to mount up in the lathe and faced off the broken threads. The drilled and tapped for 12-24. Made a stud out of a screw and thread locked it into the shaft. Then made a nut, copying the original design as closely as possible. Also there were 10-32 screws jammed into the gib holes. Fortunately they did not mess up the threads in the casting. I was able to make new 12-28 screws and got it all back together and functioning well.

Another odd thing is that the round access cover has the South Bend logo plate in the center, but it does not have the oil information plate on the bottom. I can't find where there ever was a plate mounted in that location.

I contacted Grizzly about getting a serial number card, but they only have them for lathes, non of the other machine types. That is a real shame that all that information was lost.

Anyway, here are some pics of it so far.

This unit looked like it had very little use, but it was terribly dirty. Sat uncovered for years. I could tell it was the newer style with the wide front base and the internal oil system. The old oil was clear enough I could see through it to the bottom of the sump. Where I wiped the dirt off the ways, there were no score marks, so the deal was made.

First step was to fix the feet on the cabinet. I added a 3" riser and some roller/feet units. Now I can move it around the shop to work on it.

After watching some videos and downloading the documents that were available it was time to tear into it. Started with some solvent and a brush at the top and worked my way down. Found the serial number. It is 00005S ! That seems really low. Could this be the fifth unit made after the change to the wide base and oil pump system?

Really was a struggle to get my hand inside the sump and loosen the set screw on the bottom of the rocker. It had a square head and was quite tight. Once the ram was off and the ways cleaned, most of the flaking was still there. Good news. Drained the sump and got fresh oil in it. The pump worked fine and once everything was cleaned, de-burred and put back together, I was able to run it and confirm the oil circulation before continuing.

Today I am cleaning and de-rusting the vise and the table.

Several things that don't seem right to my eye. There are some parts that have paint on them that probably shouldn't. To me this says a repaint, but the bulk of it does appear to be factory paint. Perhaps there was some sloppy touch up done by someone in the past. The lead screw on the down feed assembly was boogered up by some mook. The nut on the end of the handle was gone as were the threads on the end of the shaft. It looks like the shaft was welded back together but poorly done and the handle had been drilled and tapped for a set screw to hold it to the shaft. Of course that buggered up the shaft. And the shaft/screw assembly was bent.

Managed to get it straight enough to mount up in the lathe and faced off the broken threads. The drilled and tapped for 12-24. Made a stud out of a screw and thread locked it into the shaft. Then made a nut, copying the original design as closely as possible. Also there were 10-32 screws jammed into the gib holes. Fortunately they did not mess up the threads in the casting. I was able to make new 12-28 screws and got it all back together and functioning well.

Another odd thing is that the round access cover has the South Bend logo plate in the center, but it does not have the oil information plate on the bottom. I can't find where there ever was a plate mounted in that location.

I contacted Grizzly about getting a serial number card, but they only have them for lathes, non of the other machine types. That is a real shame that all that information was lost.

Anyway, here are some pics of it so far.