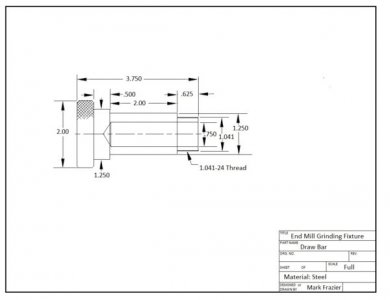

A while back, I built a tool and cutter grinder only to find it is mostly useless without a bunch of various fixtures needed to properly present the tool to the grinding wheel. So, my next step was to begin acquiring or building the needed fixtures over time. I have a really nice air bearing setup for grinding the flutes on end mills and it can be setup to also sharpen the ends of the end mills but is a lot more work than a dedicated fixture for this purpose. I spent the last few days building a dedicated fixture that is easy to set up and use to grind the ends of the end mill.

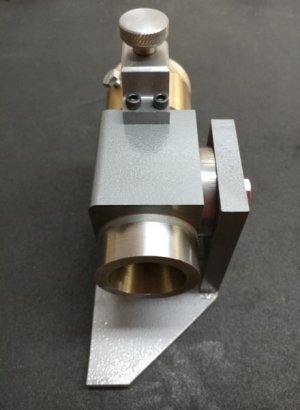

The above photos are of the completed fixture. I made it to accept 5C collets (because I have a set for the air bearing). Also in this post is the complete article of the build including photos and prints for the project in PDF format. This fixture can easily be adapted to use on many different T&C grinders. Many times an end mill only needs the ends touched up to be as good as new and this fixture makes it easy to do.

NOTE: some of you may notice the hex head bolt to lock the spindle. It won't be a problem as I only hand tighten this lock. when I get my hands on a piece of 3/4" brass rod about 1 1/2" long, I will probably make a fancy lock screw for here. ( I used material I had on hand for this project.

The above photos are of the completed fixture. I made it to accept 5C collets (because I have a set for the air bearing). Also in this post is the complete article of the build including photos and prints for the project in PDF format. This fixture can easily be adapted to use on many different T&C grinders. Many times an end mill only needs the ends touched up to be as good as new and this fixture makes it easy to do.

NOTE: some of you may notice the hex head bolt to lock the spindle. It won't be a problem as I only hand tighten this lock. when I get my hands on a piece of 3/4" brass rod about 1 1/2" long, I will probably make a fancy lock screw for here. ( I used material I had on hand for this project.