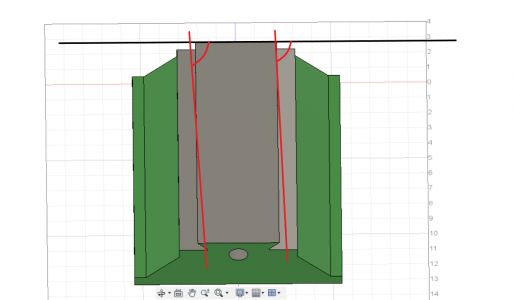

Hi guys, this is my first post here in this forum and great to be part of this community. Right now I'm in the information gathering phase, I am trying to scrape my ways and dovetails on m G0704 mill before I convert it to cnc. I've been practicing how to scrape for flatness and I've been doing some reading, mainly the Machine Tool Reconditioning book. I've tried to search for videos or articles on alignment and setting up the tools and dial indicators properly to get the proper readings. However I am having trouble figuring out how somebody would check and test for and scrape the ways on a milling base so that they are perpendicular to the back face of that base where the column attaches. I've attached a rendering image showing what the base of my mill looks like and the black line is flat up against the surface that the column attaches too. The red lines are the hypothetical errors of having the ways not perpendicular to that black line.

You would want the ways to be perpendicular to the back of the base, I am using the back as my datum or reference point.

The problem I am having is figuring out how exactly I would even go about measuring this. I have considered using a granite square lying next to the column base. But without any moving parts how would I articulate a dial indicator to make sure the granite square and the back face are perpendicular to each other. I was thinking maybe I could put some wheels under a dial indicator and run it on the back side of the base with the granite plate sitting next to it.

Once I know that the granite square and the base are parallel and square to each other then I can use something like a kingway tool to traverse the ways and have the dial indicator up against the granite square to tell me how much out of square they are.

The second challenge would be figuring out how to scrape for squareness and not just flatness and bearing surface.

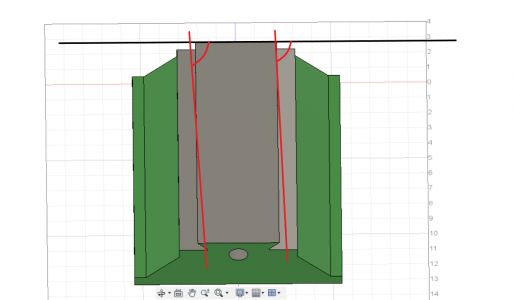

You would want the ways to be perpendicular to the back of the base, I am using the back as my datum or reference point.

The problem I am having is figuring out how exactly I would even go about measuring this. I have considered using a granite square lying next to the column base. But without any moving parts how would I articulate a dial indicator to make sure the granite square and the back face are perpendicular to each other. I was thinking maybe I could put some wheels under a dial indicator and run it on the back side of the base with the granite plate sitting next to it.

Once I know that the granite square and the base are parallel and square to each other then I can use something like a kingway tool to traverse the ways and have the dial indicator up against the granite square to tell me how much out of square they are.

The second challenge would be figuring out how to scrape for squareness and not just flatness and bearing surface.