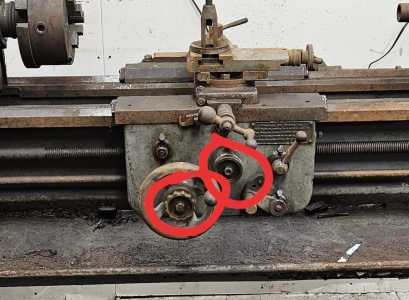

How hard is it to pull the apron on an old lathe? My Mulliner and Enlund has rubbing gears and I would like to pull the apron and see what is up.

I am guessing the lead screw and drive rod will need to come out. Do they come out without disturbing the quick change gear box or am I going to have to disassemble a lot of stuff?

I am guessing the lead screw and drive rod will need to come out. Do they come out without disturbing the quick change gear box or am I going to have to disassemble a lot of stuff?