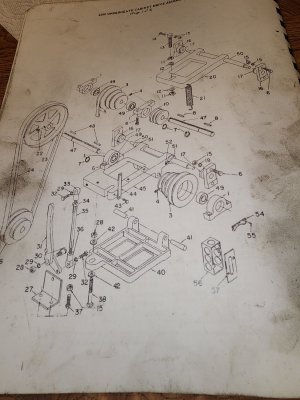

In one picture you see that the shaft has the key in it, and no bushing. The bushing was the final piece installed for the gear train.

When you take one of these apart that shaft can only be removed by pushing it to the left as the keyway isn't cut into the whole shaft.. Mr Pete mentioned that but never said how he installed the key. Hope this helps someone on their repairs.

Mike

When you take one of these apart that shaft can only be removed by pushing it to the left as the keyway isn't cut into the whole shaft.. Mr Pete mentioned that but never said how he installed the key. Hope this helps someone on their repairs.

Mike