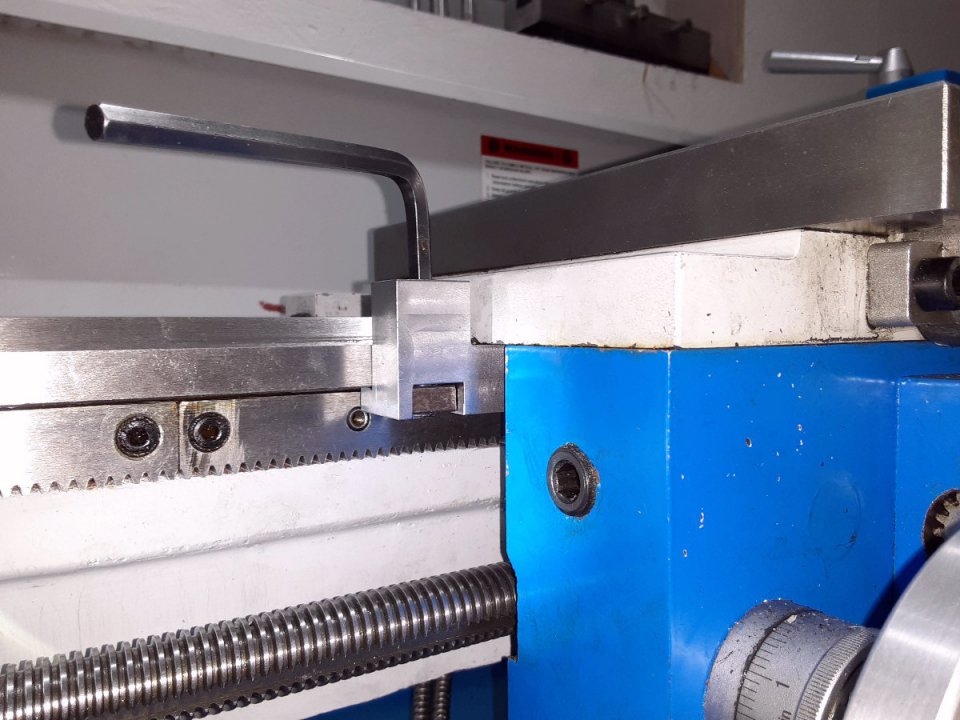

Because we ordered our lathe with DROs, dealing with facing jobs has been occasionally painful. the cross-slide DRO mostly blocks access to the saddle lock, which as you can see is a problem when facing work, especially in larger projects. After dealing with this shortcoming by all sorts of means, clamps, blocks, what-have-you, we finally decided to move the saddle lock to the other side of the saddle.

Taking out the screw and lock tab from part #58 was the easy part. Removing and reverse engineering block #57, less so, as in our lathe that block attaches to the underside of the saddle not as shown in the drawings, but with cap screws coming in from below and threaded into the saddle casting.

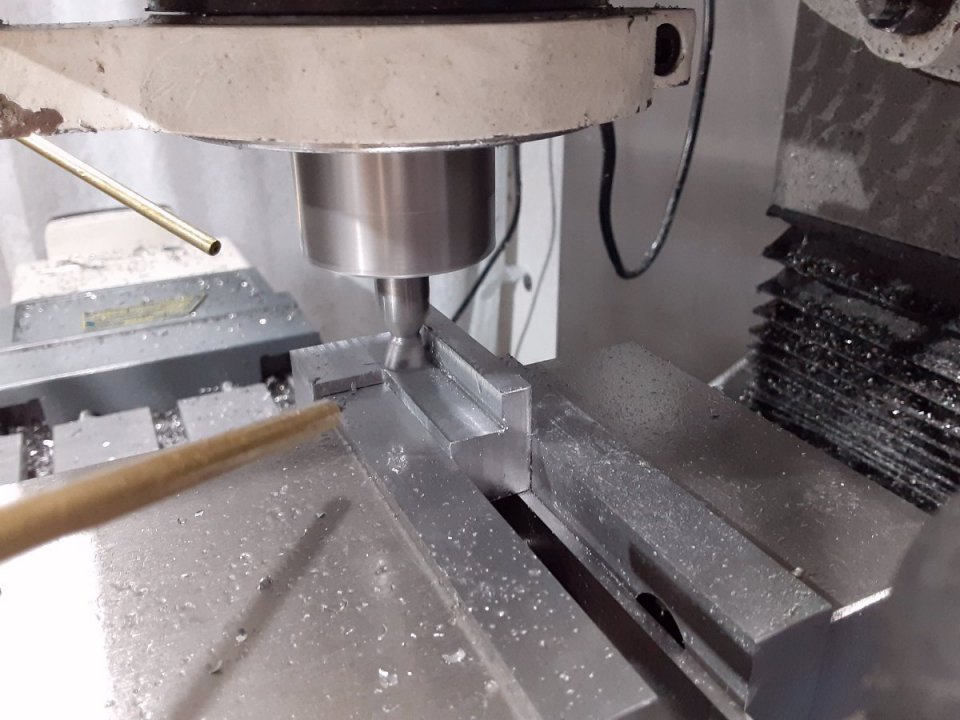

Once out, take a lot of measurements and turn to the PM30-MV to support its brother tool.

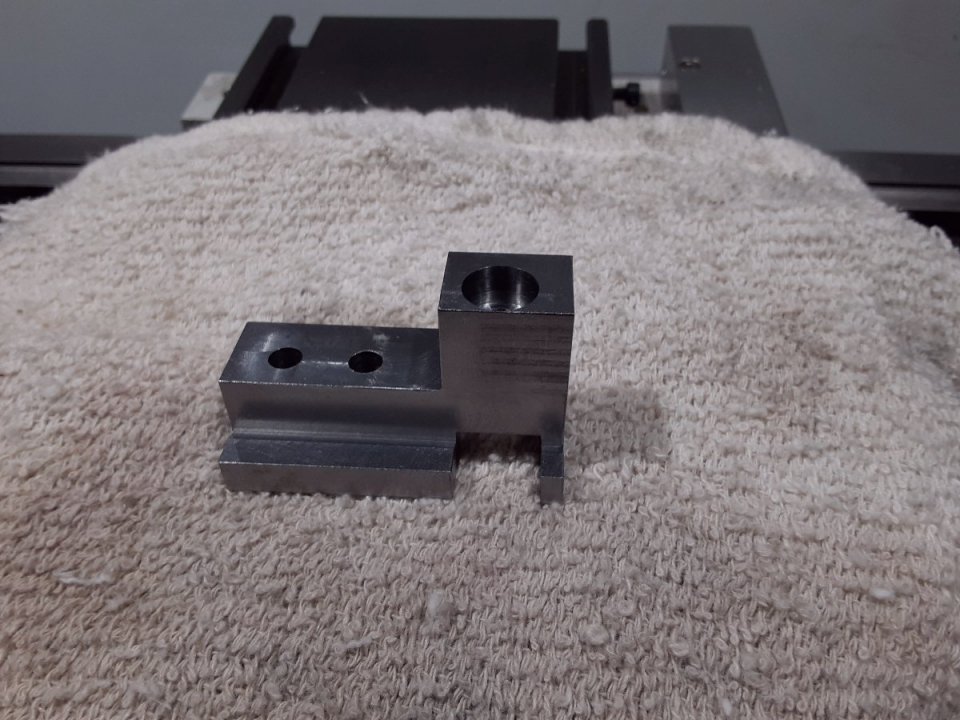

An ugly lump of A36 made into a perfect cube and then a series of cuts, holes, and slots gets it done. Precisely copied block #57, and thereby copied its errors as well. Back in the mill to fix those, and a remount. Finally done and works like it should.

Taking out the screw and lock tab from part #58 was the easy part. Removing and reverse engineering block #57, less so, as in our lathe that block attaches to the underside of the saddle not as shown in the drawings, but with cap screws coming in from below and threaded into the saddle casting.

Once out, take a lot of measurements and turn to the PM30-MV to support its brother tool.

An ugly lump of A36 made into a perfect cube and then a series of cuts, holes, and slots gets it done. Precisely copied block #57, and thereby copied its errors as well. Back in the mill to fix those, and a remount. Finally done and works like it should.