- Joined

- Apr 24, 2013

- Messages

- 713

I have been wanting to change from the HSS parting blades I have been using to carbide.

Watching some of Doubleboost's videos, the blade system from Banggood looked promising.

Looking on their site, they seemed to list both 32 mm and 26 mm blades but the more I looked it seemed that I could get the 26 mm blade and the 3 mm inserts but no holder to go with the 26 mm. After several email exchanges it became clear that they were not going to the a source for holder.

I ordered the blade and inserts and set to drawing a holder that would fit the QCTP on my G0750G 12" lathe.

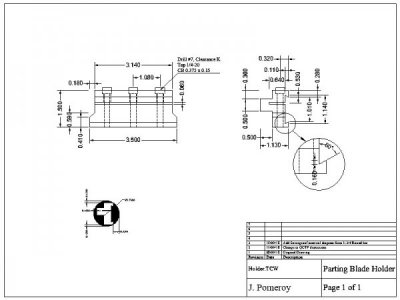

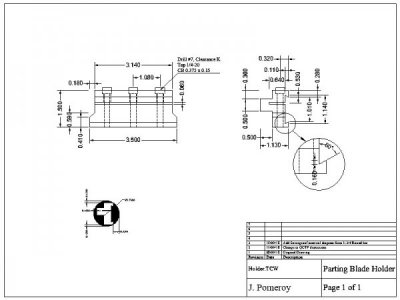

I drew up the attached sketch and proceeded to milling on a piece of 12L14 square bar that I had in the bin.

I love working with the leaded bar, it cuts like butter.

The problem was some nagging thoughts that the steel would not be strong enough to work as a blade holder. So, before the blade and inserts arrived, I decided to make another from a bar of Stressproof that I had.

Certainly not as easy to cut as the 12L14 but gave a nice finish and was doable.

Blackened both pieces when I finished and tried them out.

They both seemed to hold the blade well enough and the blade itself was very nice to use.

I will keep both and likely order another 26 mm blade with 2 mm inserts.

Watching some of Doubleboost's videos, the blade system from Banggood looked promising.

Looking on their site, they seemed to list both 32 mm and 26 mm blades but the more I looked it seemed that I could get the 26 mm blade and the 3 mm inserts but no holder to go with the 26 mm. After several email exchanges it became clear that they were not going to the a source for holder.

I ordered the blade and inserts and set to drawing a holder that would fit the QCTP on my G0750G 12" lathe.

I drew up the attached sketch and proceeded to milling on a piece of 12L14 square bar that I had in the bin.

I love working with the leaded bar, it cuts like butter.

The problem was some nagging thoughts that the steel would not be strong enough to work as a blade holder. So, before the blade and inserts arrived, I decided to make another from a bar of Stressproof that I had.

Certainly not as easy to cut as the 12L14 but gave a nice finish and was doable.

Blackened both pieces when I finished and tried them out.

They both seemed to hold the blade well enough and the blade itself was very nice to use.

I will keep both and likely order another 26 mm blade with 2 mm inserts.