The only lathe I’ve used that had a DRO was a new Enco 14x40 in a continuing education college classroom. It was very helpful. It only had carriage and cross slide readouts. A third axis for the tailstock is worthwhile in my opinion. If I ever put a DRO on my lathe it will have a tailstock readout. Lately I’ve been working on more longer pieces that need measurement references from one end. A DRO is immensely useful for long pieces so I intend to install one on my present lathe soon.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Questions on lathe DRO.

- Thread starter Flyinfool

- Start date

- Joined

- Nov 23, 2014

- Messages

- 2,612

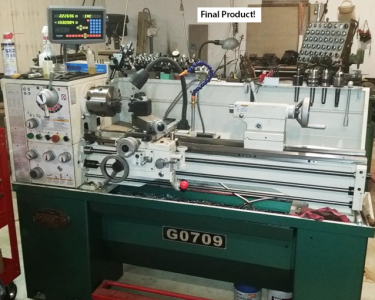

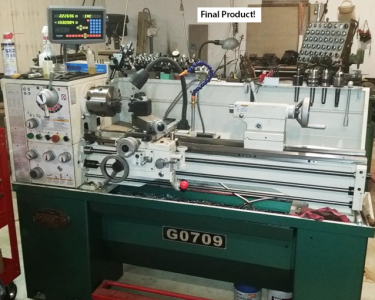

I have a 2-axis DRO on my Grizzly G0709 (14" x 40") and a shop-made digital caliper for the tail stock; I love them both! Mine has 5 micron scales on both axis', resolution is ~0.0002" on the radius (X/Y) scale. Guys will recommend 1 micron scales for the X/Y-axis. In my experience (or lack thereof. . .), I've found the 0.0002" resolution to be "good enough". I don't trust the DRO if it's ultra-critical; measure with a micrometer and adjust accordingly.

The Z-axis is really nice for shoulders and hitting features down the length of work. All of my grooving and parting tools have their width written on the tool holder. Need to cut off a 1.00" length from a rod? I butt the tool bit up to the end of the stock, hit "Z", enter the tool bit's width, hit ENTER. Then move the carriage down to my mark and part/groove, or whatever. I do the same operation on my Clausing lathe without a DRO using a dial indicator magneted to the bed. DRO is much more convenient.

Regarding the tailstock caliper, it's really not necessary, but it's nice! Want to drill a hole 3/4" deep into stock? Center drill, drill in until I eyeball depth while advancing the drill bit until I hit the full diameter. Zero the caliper and plunge away.

Bruce

The Z-axis is really nice for shoulders and hitting features down the length of work. All of my grooving and parting tools have their width written on the tool holder. Need to cut off a 1.00" length from a rod? I butt the tool bit up to the end of the stock, hit "Z", enter the tool bit's width, hit ENTER. Then move the carriage down to my mark and part/groove, or whatever. I do the same operation on my Clausing lathe without a DRO using a dial indicator magneted to the bed. DRO is much more convenient.

Regarding the tailstock caliper, it's really not necessary, but it's nice! Want to drill a hole 3/4" deep into stock? Center drill, drill in until I eyeball depth while advancing the drill bit until I hit the full diameter. Zero the caliper and plunge away.

Bruce

Last edited:

- Joined

- Dec 18, 2022

- Messages

- 1,917

The one bit of counsel I would give, is get the same brand and model DRO as you have on your Mill, this greatly minimizes the thought process when going between the 2 machines as far as the display and entry setup.So I am thinking about getting a lathe DRO. The DRO on the mill is just so convenient.

I have never seen in person a lathe with a DRO on it. Yes I have seen lots of pictures of installs that people have done on this site.

I think that installing it is the easy part.

My questions are more toward the use and functionality of it.

So it is given that I need a scale for the carriage and the cross slide.

I am still undecided as to whether I need or just want one for the tail stock?

What about the compound? Or even the angle of the compound?

For instance I was always taught that for threading the compound is set at 29.5° and the in feed is done with the compound. If I had a scale on the compound does the DRO have an input for its angle so that it would know just how far the tool has penetrated the work? Or with a DRO do you pretty much never use the compound and just do everything with the carriage and cross slide?

Does a DRO even help at all when you need to cut an angle to a dimension?

The manuals that I have seen tell you how to install it and set it up and operate the functions, but really give no info as to how to actually use it in the real world.

- Joined

- Dec 18, 2022

- Messages

- 1,917

I use the DRO on my lathe to get into the neighborhood then I take constant measurements to sneak up on the final dimension.I have a 2-axis DRO on my Grizzly G0709 (14" x 40") and a shop-made digital caliper for the tail stock; I love them both! Mine has 5 micron scales on both axis', resolution is ~0.0002" on the radius (Z) scale. Guys will recommend 1 micron scales for the Z-axis. In my experience (or lack thereof. . .), I've found the 0.0002" resolution to be "good enough". I don't trust the DRO if it's ultra-critical; measure with a micrometer and adjust accordingly.

The X/Y-axis is really nice for shoulders and hitting features down the length of work. All of my grooving and parting tools have their width written on the tool holder. Need to cut off a 1.00" length from a rod? I butt the tool bit up to the end of the stock, hit "X/Y", enter the tool bit's width, hit ENTER. Then move the carriage down to my mark and part/groove, or whatever. I do the same operation on my Clausing lathe without a DRO using a dial indicator magneted to the bed. DRO is much more convenient.

Regarding the tailstock caliper, it's really not necessary, but it's nice! Want to drill a hole 3/4" deep into stock? Center drill, drill in until I eyeball depth while advancing the drill bit until I hit the full diameter. Zero the caliper and plunge away.

Bruce

View attachment 490640

View attachment 490639

- Joined

- May 3, 2017

- Messages

- 1,999

I'd like to see them if it's not too much trouble.I could find pictures if there was enough interest.

Regards

- Joined

- Oct 14, 2013

- Messages

- 1,029

As they say, "pictures or it didn't happen"...

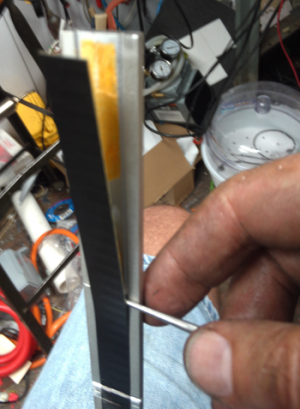

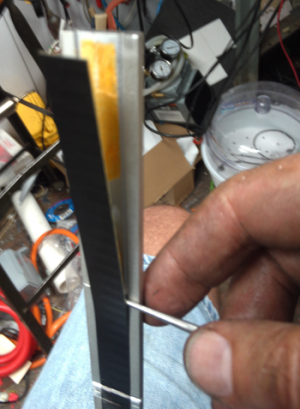

I machined a flat on the side of the moving part parallel to the motion and a matching one on the base. I peeled the scale off of an iGaging scale

And used black max (rubber toughened super glue) to bond it on. The reader was trimmed down and boxed in a fancy Copper housing.

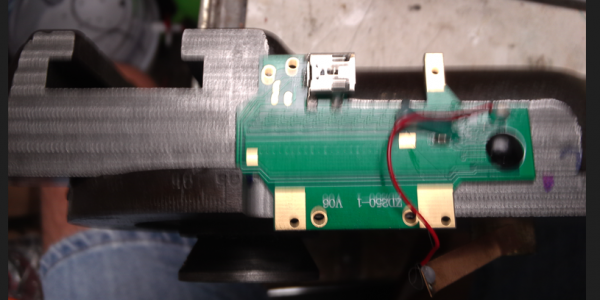

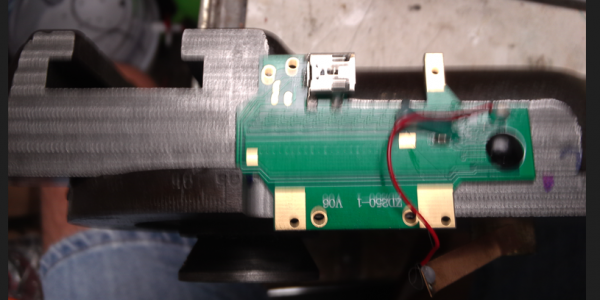

Here I'm working out what I will hack off of the board ;-)

This is the trimmed board, upside down.

The inside of the reader, mounted:

I machined a flat on the side of the moving part parallel to the motion and a matching one on the base. I peeled the scale off of an iGaging scale

And used black max (rubber toughened super glue) to bond it on. The reader was trimmed down and boxed in a fancy Copper housing.

Here I'm working out what I will hack off of the board ;-)

This is the trimmed board, upside down.

The inside of the reader, mounted:

- Joined

- Apr 29, 2019

- Messages

- 2,106

The one bit of counsel I would give, is get the same brand and model DRO as you have on your Mill, this greatly minimizes the thought process when going between the 2 machines as far as the display and entry setup.

Unfortunately the DRO on my mill is 40+ years old and they have been out of business for more than 30 of those years. My mill DRO has many features that I have not been able to decipher how to use. Never was able to even find a manual for it. I will keep it until it dies then upgrade.