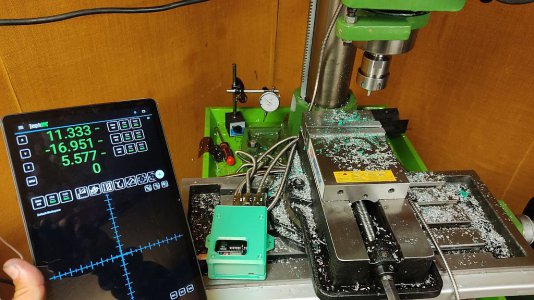

I somewhat recently picked up a deceased estate 1981 RF30 that had never been so much as plugged in, after cleaning off all the very much hardened shipping oil I figured it'd be rude not to add a DRO, so ordered a TouchDRO from Yuriy and some SINO KA500 slimline scales from Amazon.

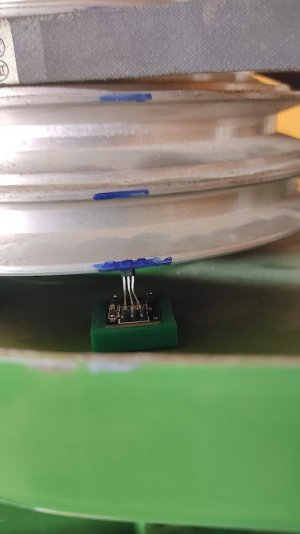

A couple mates of mine modified the .STL files and 3D printed a case for the TouchDRO

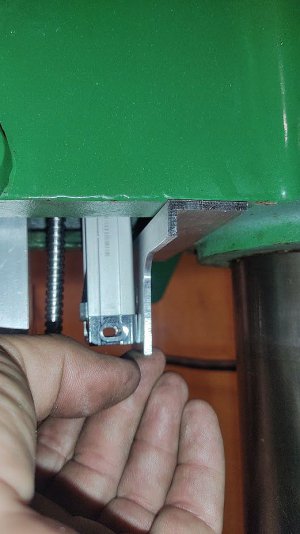

X axis install was as simple as removing the stops and mounting the scales backing plate using the factory dovetail and a little bit of milling to the bracket that came with the scales for the read head

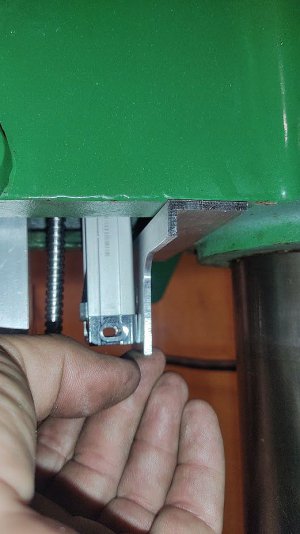

Z axis took a bit more effort

Think I might flip the scale over and run the cable out through the top and out the back of the belt cover yet, just so it's not hanging down by the spindle and the head height crank etc.

A couple mates of mine modified the .STL files and 3D printed a case for the TouchDRO

X axis install was as simple as removing the stops and mounting the scales backing plate using the factory dovetail and a little bit of milling to the bracket that came with the scales for the read head

Z axis took a bit more effort

Think I might flip the scale over and run the cable out through the top and out the back of the belt cover yet, just so it's not hanging down by the spindle and the head height crank etc.