Have you tried adjusting the belt? Easy to do and may solve your problem.

Not sure how this one would be adjusted, tension is achieved simply through the motor "hanging" in the lower housing.

Have you tried adjusting the belt? Easy to do and may solve your problem.

This is what I have now. It is delaminating quite badly, hence the new belt. Also, it will run with the "click - click - click - click" of the connector every time it passes over the pulley.

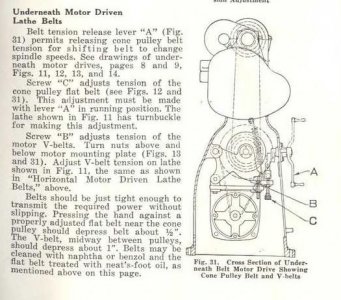

No, there is a belt-tension adjustment screw that is used to adjust the primary belt tension. (There is a different adjustment for the V-belt tension between the motor and the jackshaft.)Not sure how this one would be adjusted, tension is achieved simply through the motor "hanging" in the lower housing.

No, there is a belt-tension adjustment screw that is used to adjust the primary belt tension.

Without pictures it's all just talk.Hi, I have a 1935 SB 16. Is yours an under motor or countershaft style? Mine is a countershaft type and needed a rebuild. I removed the spindle and pulley and then cut poly v grooves in the largest diameter pulley. A 2" poly v belt was purchased along with a spring loaded idler to mount between the motor and headstock. The drive pulley was sized to provide 800 rpm at the spindle with a 1750 rpm motor 3ph. and a vfd. I haven't touched the belt since. I overcame the lack of torque at slower speed because my old 16 has a 2 stage back gear in place of the smallest pulley with ratios of 3.75 and 6.0 to 1 for heavy turning. Pol v belts are the same as serpentine auto belts and come in almost every size imaginable.

What part of the description that I posted didn't you understand? I have metal to cut and don't stand in front of my machine taking pictures.Without pictures it's all just talk.