- Joined

- Apr 25, 2024

- Messages

- 3

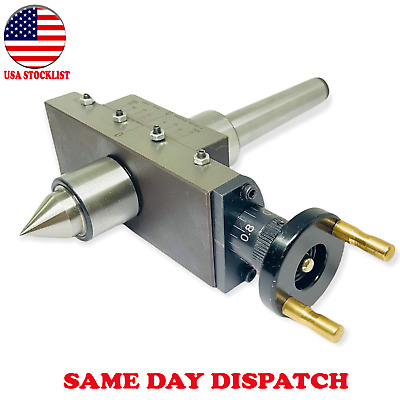

How is the moveable center kept horizontal? Or do you just bang it in tight and be careful not to bump it?

Maybe this is a dumb question and I'm just not seeing something.

Maybe this is a dumb question and I'm just not seeing something.