- Joined

- May 27, 2016

- Messages

- 3,479

I have been getting into setting up my air compressor, to achieve cleaned up, dried out, air. It's about looking for all the right stuff to add onto the basic machine, on which HM members have been super-helpful. The kit is a 3HP Hyundai 100 litres (about 26.4 gallons US). For many reasons, mostly about noise and wear life longevity, I chose the large cylinder slow running oiled type, reasoning I could filter the air clean before putting it into the shop pipes.

The compressor comes with a basic pressure control switch, into a very compact regulator of the cheapest sort. There are two hose output connectors, awkwardly sticking out at right angles. Just to discover the thread type (BSPT or NPT or whatever), we get to taking stuff apart.

OK - so now you know I am the type who would take stuff apart without even running it for the first time!

_ _ _

_ _ _

Sure, there is a pressure setting knob, but I had been expecting a "regulator", with diaphragm, something like is on top of the oxygen bottle.

This one has what looks like a 4-way junction only. So I start taking it apart..

_ _ _

_ _ _

The threads tuned out to be 19TPI BSPP taper, so if I want more choice in the add-ons, I will need a thread adapter. They are cheap, and available on eBay.

I know that taper threads are supposed to seal against the deforming metal, but these joints also had some kind of varnish-like goop in the threads.

Digging into the centre of the label on the knob did not lead to any way to get the knob off.

_ _ _

_ _ _

The way in turned out to be a tiny hex socket grubscrew threaded into the plastic that sticks into the space to bump against the knob thread start. It does not look like it will last long. Taking off the knob, we discover a fair amount of the regulator mechanism resides up the middle of the knob.

_ _ _ _

_ _ _ _

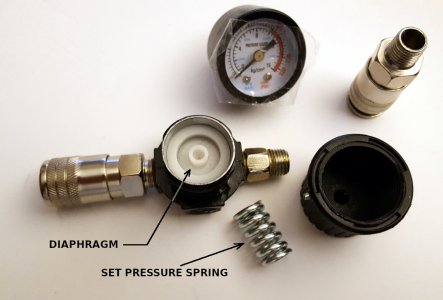

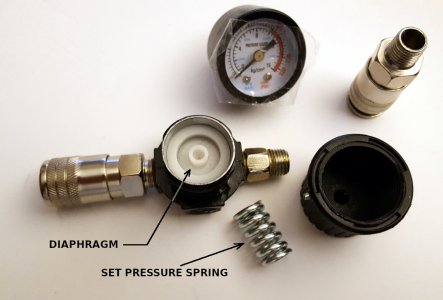

There is another, smaller spring on the underside of the plastic diaphragm valve. So OK - it is a normal diaphragm regulator, just a very small diameter one. This may be why these little low cost things may be of limited accuracy, as was mentioned to me by @rabler in another thread. Anyway, I fished out the diaphragm.

_

_

The plastic diaphragm has a sliding O-ring seal. That is the feature that allows it to move up and down, as opposed to flexible diaphragms having fixed sealing around the edge. The diaphragm is now a piston! I chose not to mess with the valve below. It seemed tight.

Water separator units, including one of these fitted as a unit, sell for as little as £7.50 (about $9). There are many just like it, getting up to around $30, before one starts to perceive a build quality change. That said, I think lots of folk might get along just fine for years with these cheap builds. If it "just works", I don't think we care very much.

So that's it folks! A bit heavy on the pictures, and possibly of limited interest, but I post it anyway. It gives opportunity to say "I told you so" later, when the perchant to take stuff apart does not end well.

[Yes - I do get it that compressed air is dangerous!. In my defence, I don't expect it will be going back onto the compressor! ]

The compressor comes with a basic pressure control switch, into a very compact regulator of the cheapest sort. There are two hose output connectors, awkwardly sticking out at right angles. Just to discover the thread type (BSPT or NPT or whatever), we get to taking stuff apart.

OK - so now you know I am the type who would take stuff apart without even running it for the first time!

_ _ _

_ _ _

Sure, there is a pressure setting knob, but I had been expecting a "regulator", with diaphragm, something like is on top of the oxygen bottle.

This one has what looks like a 4-way junction only. So I start taking it apart..

_ _ _

_ _ _

The threads tuned out to be 19TPI BSPP taper, so if I want more choice in the add-ons, I will need a thread adapter. They are cheap, and available on eBay.

I know that taper threads are supposed to seal against the deforming metal, but these joints also had some kind of varnish-like goop in the threads.

Digging into the centre of the label on the knob did not lead to any way to get the knob off.

_ _ _

_ _ _

The way in turned out to be a tiny hex socket grubscrew threaded into the plastic that sticks into the space to bump against the knob thread start. It does not look like it will last long. Taking off the knob, we discover a fair amount of the regulator mechanism resides up the middle of the knob.

_ _ _ _

_ _ _ _

There is another, smaller spring on the underside of the plastic diaphragm valve. So OK - it is a normal diaphragm regulator, just a very small diameter one. This may be why these little low cost things may be of limited accuracy, as was mentioned to me by @rabler in another thread. Anyway, I fished out the diaphragm.

_

_

The plastic diaphragm has a sliding O-ring seal. That is the feature that allows it to move up and down, as opposed to flexible diaphragms having fixed sealing around the edge. The diaphragm is now a piston! I chose not to mess with the valve below. It seemed tight.

Water separator units, including one of these fitted as a unit, sell for as little as £7.50 (about $9). There are many just like it, getting up to around $30, before one starts to perceive a build quality change. That said, I think lots of folk might get along just fine for years with these cheap builds. If it "just works", I don't think we care very much.

So that's it folks! A bit heavy on the pictures, and possibly of limited interest, but I post it anyway. It gives opportunity to say "I told you so" later, when the perchant to take stuff apart does not end well.

[Yes - I do get it that compressed air is dangerous!. In my defence, I don't expect it will be going back onto the compressor! ]

Last edited: