- Joined

- Oct 7, 2020

- Messages

- 2,113

I finished up the Clough42 ELS install on my PM-1236T the other night. It works great, it was a fun project that will make life a tad easier when I need to cut metric threads. And the fact that a person can change the feed rate on the fly is pretty cool also.

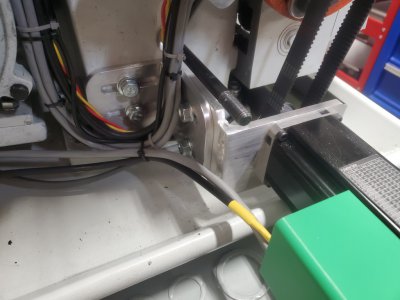

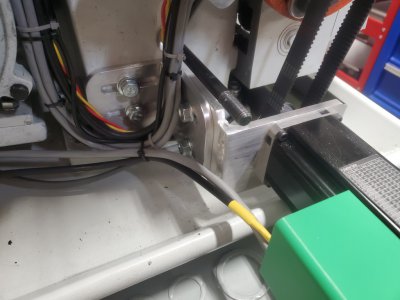

Anyway, here are a few photos of the install.

The two 18mm pulleys I got had 6mm keyway slots, I needed 5mm slots. So, I made a 5mm keyway broch and cut the correct size slot. I also milled the shoulder off of all of the pulleys and redrilled them for the set screws.

3D printed some prototype brackets to make sure things would fit. After I sure everything would work, I proceeded to slot the aluminum brackets. My aluminum welding sucks so no photos of that.

I 3D printed a mount for the control head to clamp to my DRO mounting arm.

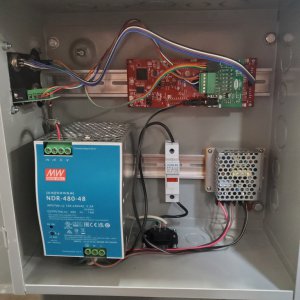

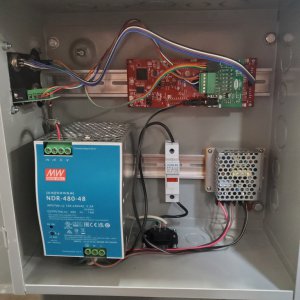

Since my electronics cabinet didn't have a mounting plate for the back I mounted the mounting rails directly to the cabinet. At that point I needed some standoff pads, I printed some out of Flexable TPU.

I also printed a patch panel. And a cover for the electrical connectors on the Servo motor.

Anyway, here are a few photos of the install.

The two 18mm pulleys I got had 6mm keyway slots, I needed 5mm slots. So, I made a 5mm keyway broch and cut the correct size slot. I also milled the shoulder off of all of the pulleys and redrilled them for the set screws.

3D printed some prototype brackets to make sure things would fit. After I sure everything would work, I proceeded to slot the aluminum brackets. My aluminum welding sucks so no photos of that.

I 3D printed a mount for the control head to clamp to my DRO mounting arm.

Since my electronics cabinet didn't have a mounting plate for the back I mounted the mounting rails directly to the cabinet. At that point I needed some standoff pads, I printed some out of Flexable TPU.

I also printed a patch panel. And a cover for the electrical connectors on the Servo motor.