- Joined

- Apr 8, 2013

- Messages

- 1,980

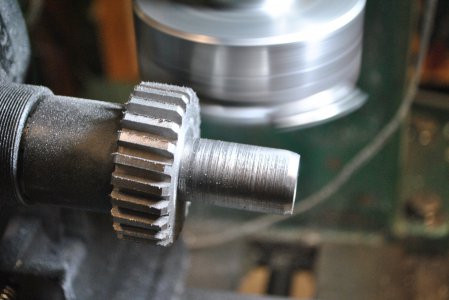

I 'm making a 24 to 1 worm gear transmission for a future project. This is my first time making worm gears. I started by making a horizontal fly cutter with the 4 tpi tooth profile to cut the teeth on the mill. With a cast iron blank this was the mother of all interrupted cuts and my spin indexer was not up to it. Next I tried making a million passes using a slitting saw but could not get the involute right nor duplicate the constant spiral of the worm. Finally I did what I should have done on day one. I made a hob and hardened it. This worked pretty slick after I gashed the blank with a slitting saw and followed up with the fly cutter. The teeth were about 75% formed and the hob finished the job in 15 minutes. I've included some video of cutting the blank with the hob and also running the worm and worm gear that will be meshed together in the final product. They running here at 600 rpm.