Many of this style lathe the toothed belt is used for low speeds and connected to the spindle by a v belt not seen in your images.

In other words it will no longer be required with a motor capable of running speeds as low as 300 rpm

Some the toothed belt is required. I cannot tell from images alone.

If its not required, leave it disconnected or remove it entirely.

Use this motor:

https://www.servomotorkit.com/produ...river-2hp-16-nm-torque-strait-shaft-flat-face

Use this pulley:

https://www.servomotorkit.com/produ...for-10-mm-wide-belts-15-mm-bore-5-mm-key-fits

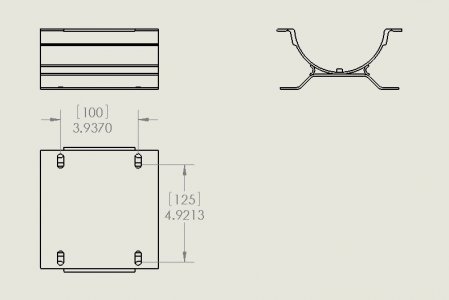

Make your own side mount. I have a kit just have not found time to list it. Besides most will have the metal required and not want to buy more small pieces at retail prices.

The motor rpm is 300 to 3,000 RPM.

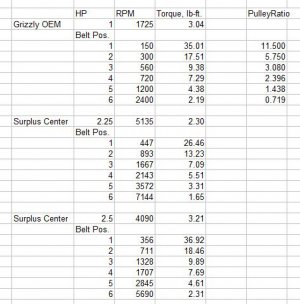

Resulting estimated spindle speeds:

60 mm pulley motor to 119 mm pulley on spindle:

Spindle runs 160 RPM through 1,600 RPM That is all I personally would ever use.

slower is possible by running the motor at 200 rpm but I do not recommend it.

60 mm pulley to 100 mm pulley: 180 to 1,800

60 to 65: 290 to 2,900

I see no reason to even consider the next 3 faster spindle speeds.