- Joined

- Oct 29, 2023

- Messages

- 37

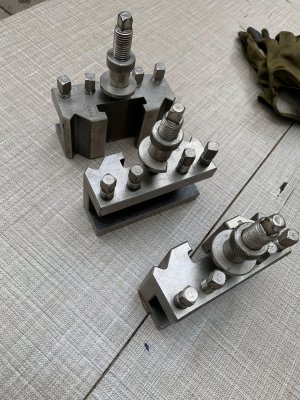

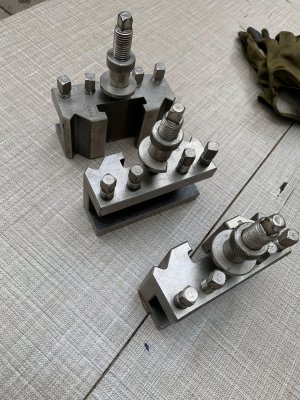

My lathe is REIDEN-t200, using 125 quick change tool holder, only 3 tool holders when I bought the lathe, I need more, and then I tried to make some by myself, using the milling machine to make T slot, V slot, although very fast, but the accuracy of the production will have some defects, and beauty is also a problem.

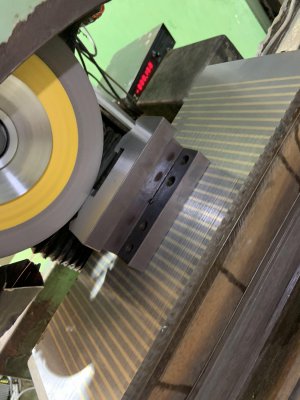

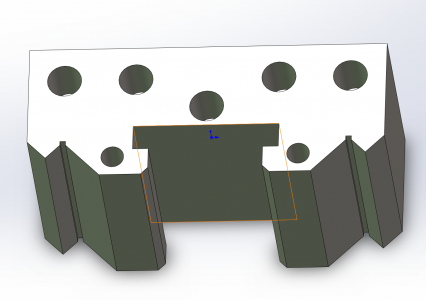

After I began to learn to use EDM, I tried to cut the outer outline, which made me experience: easy processing, more styles can be made, and more practical.

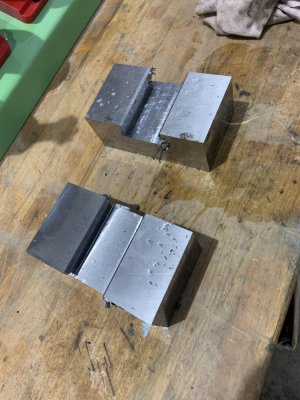

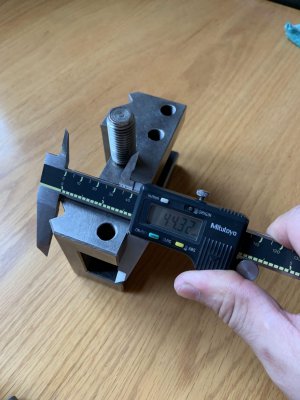

I re-purchased some steel plates, the size is accurate 125*70*50, so that the outer size machining is omitted.

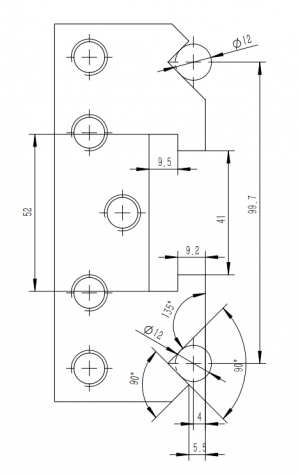

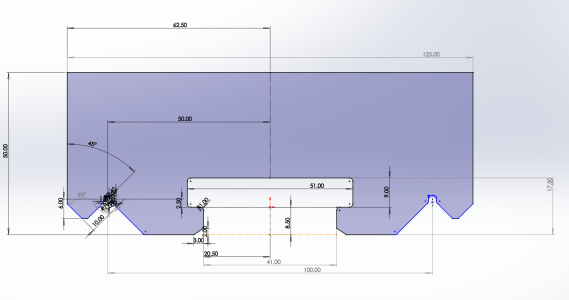

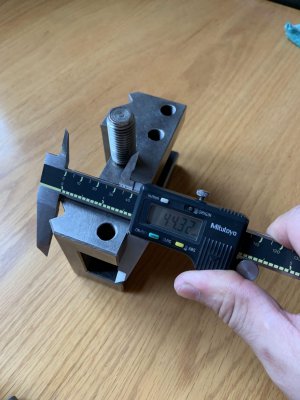

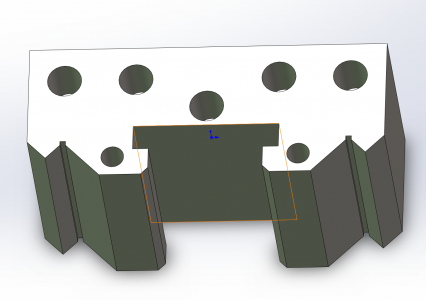

This is the lathe mounted tool holder, I carefully measured, recorded detailed data, and then used SW to complete the drawing

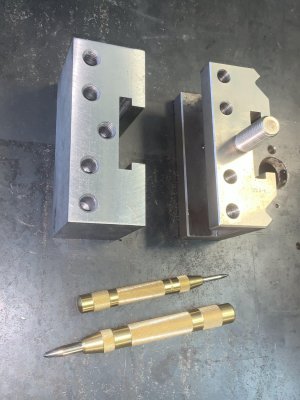

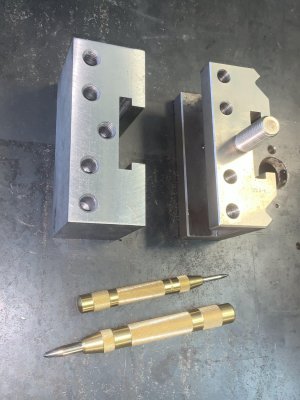

In 2021, two tool holders were made using a manual milling machine

After I began to learn to use EDM, I tried to cut the outer outline, which made me experience: easy processing, more styles can be made, and more practical.

I re-purchased some steel plates, the size is accurate 125*70*50, so that the outer size machining is omitted.

This is the lathe mounted tool holder, I carefully measured, recorded detailed data, and then used SW to complete the drawing

In 2021, two tool holders were made using a manual milling machine