Hi @verbotenwhisky

I am moving our interaction to this thread. Since it deals with the TPI generating Excel Workbook, it is more appropriate here.

"TPI Many Lathes add PM1236-draft and PM1440HD-draft N203_1048 Zipped.zip" which was posted at

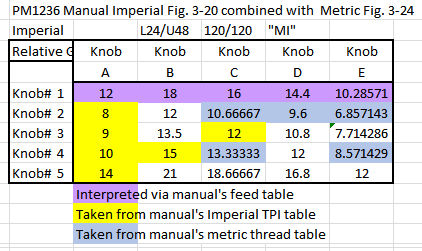

In this version, I think I figured out all of your gear box ratios in the PM1230 .... with the concern about the knob#1 values being taken from the manuals Feed rates. See the attached table. When you have time if you check the first row for accuracy we will know for sure if the gear box ratios are correct or not. However, this says nothing about the accuracy of the feed rates.

By the way, there are 5 knob settings that all yield 12TPI. Maybe you can just scratch a thread and compare the one from A-1 to B-2 to see if they are the same.

Dave L.

I am moving our interaction to this thread. Since it deals with the TPI generating Excel Workbook, it is more appropriate here.

I understand busy. What discrepancy were you finding? Feed rates or threading? So much time has passed and because I was also helping others I have gotten a little confused about what I posted for you about your PM1230. I do recall that I made some other changes and then posted the PM1230 sheet, (not the PM1230T) in with the version that I posted for Larry$, the PM1440HD sheet. The Workbook name you should be using is:I finally had a chance to look at the spread sheet, you were correct, it is a bit off due to the settings on my lathe, I am trying to calculate some of the gearing but unfortunately

"TPI Many Lathes add PM1236-draft and PM1440HD-draft N203_1048 Zipped.zip" which was posted at

I edited the PM1440HD-draft worksheet slightly above and deleted the attachment above.... and I am attaching the corrected version here. Still a draft. No changes to the PM1236 sheet.

In this version, I think I figured out all of your gear box ratios in the PM1230 .... with the concern about the knob#1 values being taken from the manuals Feed rates. See the attached table. When you have time if you check the first row for accuracy we will know for sure if the gear box ratios are correct or not. However, this says nothing about the accuracy of the feed rates.

By the way, there are 5 knob settings that all yield 12TPI. Maybe you can just scratch a thread and compare the one from A-1 to B-2 to see if they are the same.

Dave L.

Last edited: