- Joined

- Nov 2, 2012

- Messages

- 415

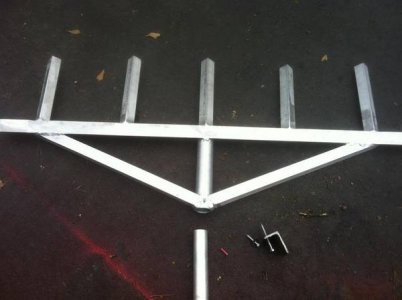

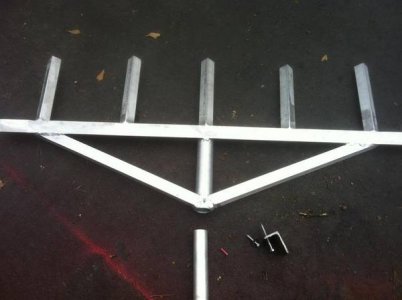

I also worked on the venerable 4x6 and its lack of table yesterday, but I made the flip-up variety as outlined in mikesworkshop. It's all steel made from scrap I had on hand.

I'll probably do the fence next, but as is, it's going to be a bunch safer to use vertically now.

I'll probably do the fence next, but as is, it's going to be a bunch safer to use vertically now.