- Joined

- Mar 10, 2015

- Messages

- 309

My next project will be a Flip top R8 collect holder wrack for my new mill.

Brought these parts home on Thursday to do a shop project with my son . He is 17 yo and autistic . We were supposed to start tonight but he was not interested IMO ( all bc Mom says its raining). Anyways fathers day was the first day he spent time in shop and I started to tech him some basics . He learned some safe shop practices, names of tools and how to use the fractional decimal chart. Than how to indicate as he dialed in new mill, He than trammed the mill and indicated in vise. He than took his first cut. So I figured this would be perfect first real project to teach layout, drill tap, riveting and assembly.

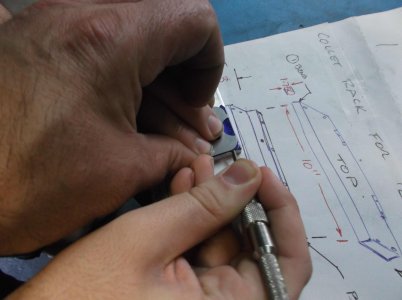

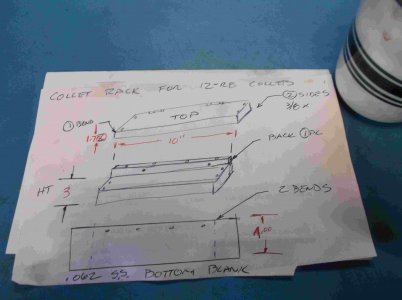

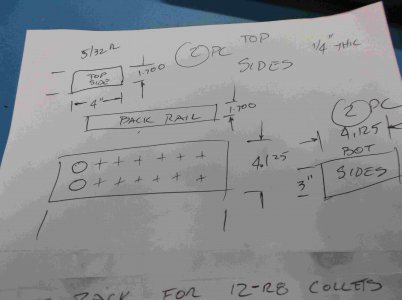

I wanted to work on something basic with my son to gain his interest for future projects . On Wed I spotted a nice pc of stainless steel that someone gave me not to long ago under my bench. I was going to make a rotating collet holder but after I noticed the material again on Wednesday that was it .Perfect. So the next morning drew up a basic idea from an ole Bridgeport collet rack . After bending the top I then changed the design on the fly. The bottom was supposed to have two bends but didnt realize the material was 1/8 thk stainless when I first came up with the original design. . Prob would of used .062 allum or something . And o boy was I sorry to use stainless when I decided to punch out the holes. The press we have didnt like one inch diam punch 1/8 thk SS . I pushed it too, had to reinforce the stripper ( hold down) to get through the Job. I had already layed it out so did not want to turn back had 15 min to finish too ... Lol... I did it that way because it was rotated symmetrically with only 3 shifts and a flip. We were supposed to work on when I got home today. Tonight I was tempted to finish bc im so project orientated but will have to wait and finish when my son is ready to have shop time with dad.

for my new mill.

Brought these parts home on Thursday to do a shop project with my son . He is 17 yo and autistic . We were supposed to start tonight but he was not interested IMO ( all bc Mom says its raining). Anyways fathers day was the first day he spent time in shop and I started to tech him some basics . He learned some safe shop practices, names of tools and how to use the fractional decimal chart. Than how to indicate as he dialed in new mill, He than trammed the mill and indicated in vise. He than took his first cut. So I figured this would be perfect first real project to teach layout, drill tap, riveting and assembly.

I wanted to work on something basic with my son to gain his interest for future projects . On Wed I spotted a nice pc of stainless steel that someone gave me not to long ago under my bench. I was going to make a rotating collet holder but after I noticed the material again on Wednesday that was it .Perfect. So the next morning drew up a basic idea from an ole Bridgeport collet rack . After bending the top I then changed the design on the fly. The bottom was supposed to have two bends but didnt realize the material was 1/8 thk stainless when I first came up with the original design. . Prob would of used .062 allum or something . And o boy was I sorry to use stainless when I decided to punch out the holes. The press we have didnt like one inch diam punch 1/8 thk SS . I pushed it too, had to reinforce the stripper ( hold down) to get through the Job. I had already layed it out so did not want to turn back had 15 min to finish too ... Lol... I did it that way because it was rotated symmetrically with only 3 shifts and a flip. We were supposed to work on when I got home today. Tonight I was tempted to finish bc im so project orientated but will have to wait and finish when my son is ready to have shop time with dad.

Yes the design was changed again on the fly . OiriginalyI wanted a 12 collet wrack when I left home. But than by lunch time . I was gona have a flip top for twelve collets and two extra holes on end for 2 drill chucks . But changed that again... didn’t like the way it looked. Cool idea tho... So than I made a separate holder for them and ended up making this wrack which will hold 16 collets ..

So thats it . Stay tuned for the finished product. Its and easy design, but know its gona come out good lookin when finished.