- Joined

- Nov 6, 2015

- Messages

- 24

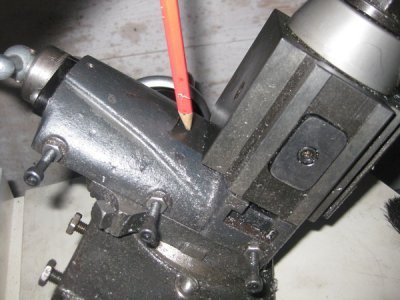

Hello, I bought a Craftsman 12" (101.07403) lathe last Sunday. It came with minimal tooling, but some goodies that made up for that. (Taper attachment, steady rest, milling attachment). I will have questions about inspecting it for wear later, but aside from that, it appears in decent shape. I believe it is an early 50's model, and has the standard change gears. I intend to start tearing it down to rebuild it and repaint it this weekend. I would like to get a manual, and from the research I have done the Manual of Lathe Operations and Machinists Tables by Atlas Lathe Co. sounds like the best reference for my lathe. There is one available on e-bay, and apparently I can order a reprint as part of a data pack from lathes.co.uk.

Has anyone ordered the data pack from lathes.co.uk, and if so is it worth paying extra for?

Additionally I can apparently order a manual from Clausing as well, can anyone confirm this?

Aside from the manual, I would like to order some tooling, and honestly I want to stay away from e-bay. As far as I can tell I need Morse Taper # 2 attachments for the tailstock? Is that correct, and any advice on where to purchase?

Which collets should I use?

Finally, at least for this post, I would like to determine if anyone sells a quick change tool post that will slap right on in place of the standard tool post. Any ideas, and wee to go for cutting tools?

I know its a lot, thanks in advance for the help! And don't worry ill cruise through some old threads. Ive done some homework, but might was well cut to the chase and let you know the info I need.

Cheers,

Vulcan

Has anyone ordered the data pack from lathes.co.uk, and if so is it worth paying extra for?

Additionally I can apparently order a manual from Clausing as well, can anyone confirm this?

Aside from the manual, I would like to order some tooling, and honestly I want to stay away from e-bay. As far as I can tell I need Morse Taper # 2 attachments for the tailstock? Is that correct, and any advice on where to purchase?

Which collets should I use?

Finally, at least for this post, I would like to determine if anyone sells a quick change tool post that will slap right on in place of the standard tool post. Any ideas, and wee to go for cutting tools?

I know its a lot, thanks in advance for the help! And don't worry ill cruise through some old threads. Ive done some homework, but might was well cut to the chase and let you know the info I need.

Cheers,

Vulcan