So, did I miss something, did you bring this home already or is that still in the plan?

Ha - no - it comes home anytime between tomorrow and Friday. Spare time on my hands on a Sunday and the desire to get some early input from the crowed prompted me to go ahead and post. Plus, now, what ever foolishness I get into on the move - you guys can stand on the side line and enjoy.

OK in lieu of hand wheels, you could try what This Old Tony on youtube did: he made a box with 3 encoders, and they function as his hand wheels.

Here's his overview, and check out 17:38 for a description of his handwheel 'replacements'...

Oh, man, I love TOT.

If my control box was talking to my drives - I would probably do this just for the pure ease - in the short run.

And I admittedly have only turned the crank on a mill 3 times in my life - two of which were last week looking at mills...

But I would like to have a manual handle in the end.

I like the feeling and the precision of moving the table like this.

Maybe I will find it useless one day - but going in - manually operable is my goal if I can.

First, I would say to do whatever @JimDawson says, I know it seems like just putting handles on might be the easiest way but it might not for several reasons. Jim has done a ton of these control retrofits and will be able to steer you in the right direction.

Oh - without Jim's input - I wouldn't even be posting on the right forum...

Incorporate some sort of seal (lip, o-ring, labyrinth or brush) where the shaft penetrates the drive cover(s). Chips in the cog belt = no good.

There is a sub-forum on H-M for requesting parts to be made. Sketch up what you want and . . .

Good head's up on both fronts. Much appreciated.

Find one that has an OD the same as your pulley ID, and stick a handwheel shaft inside. Tighten bolts, and it expands/contract and locks the handwheel shaft to the pulley.

Check out Fenner Drives for an overview of types.

Many varieties, some are self-aligning. Available on ebay.

Like concept - but not sure there will be space for the lock device between OD of screw's nut and pulley's ID. Also - how would it lock to the pulley? Just press in?

This is the really simple way to do it. ^^^^^^^^ My machine handwheels are attached by a similar method.

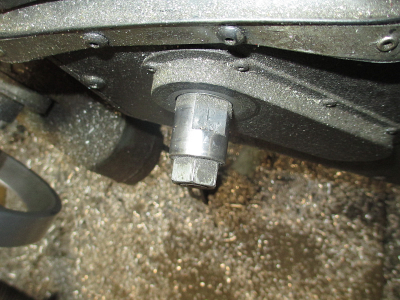

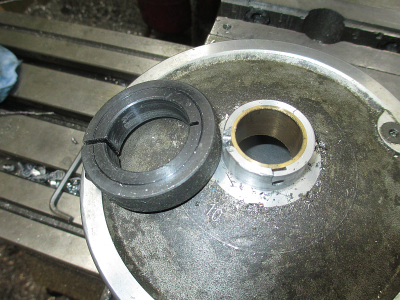

I just bored the handwheel to be a tight slip fit on the shaft, and turned the OD of the flange to fit a set collar. Tighten the set collar, it is just held with a friction fit, just squeezes the handwheel hub onto the shaft. Have not had a problem with them coming loose. Actually works the same as that hub that @spumco shows above but only costs a few $. Both require machining so that part of it is a wash.

Jim - I read this twice - but couldn't quite decipher.

I just bored the handwheel to be a tight slip fit on the shaft, - CHECK

turned the OD of the flange to fit a set collar. - What is a set collar? (bracing for the tomatoes)

Can't quite vision this assembly - but would like to!