-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heavy 10 project

- Thread starter woodtickgreg

- Start date

- Joined

- Jun 22, 2012

- Messages

- 1,552

Today I was thinking what was I doing last year at this time? I was painting the lathe on the 4th of July in 100 degree plus heat. Then I thought, the lathe still is not done, I think this happens to a lot of us. Life and other projects get in the way sometimes. I am kinda caught up with other stuff and I really need the lathe so I guess it's time to get busy. I'll post a few pics of where I am at so far as I have made some progress since my last posting.

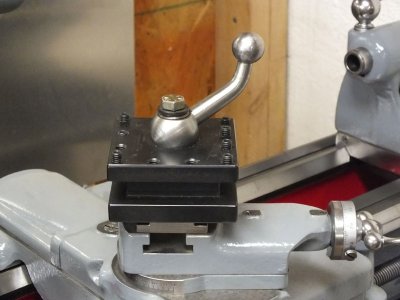

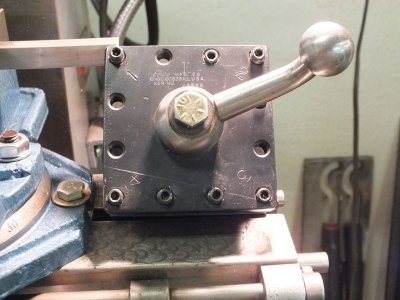

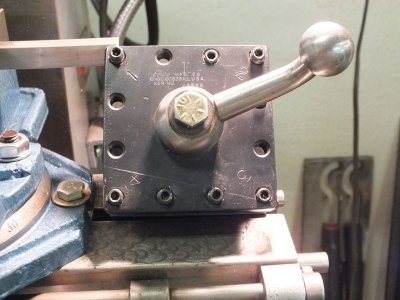

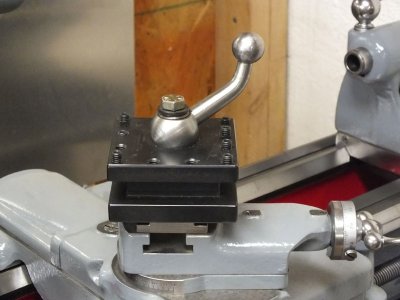

Today I was thinking what was I doing last year at this time? I was painting the lathe on the 4th of July in 100 degree plus heat. Then I thought, the lathe still is not done, I think this happens to a lot of us. Life and other projects get in the way sometimes. I am kinda caught up with other stuff and I really need the lathe so I guess it's time to get busy. I'll post a few pics of where I am at so far as I have made some progress since my last posting.In the first pic you can see the lathe moved against the wall and in it's final resting place. I got a large sheet of aluminum from work for free so I put it on the wall for a backsplash. You can also see where the vfd is going to go at eye level to the left of the lathe. I also found this indexible tool holder in a bucket of scrap metal that I got from the guy I bought my burke mill from. I have to machine the clamp block, but I can do that on the burke! I took some pics of the holder and any numbers I could find on it, it's like new but missing a few screws. Anybody know anything about this holder?

Last edited:

- Joined

- Jun 22, 2012

- Messages

- 1,552

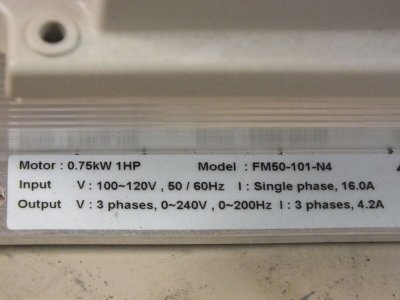

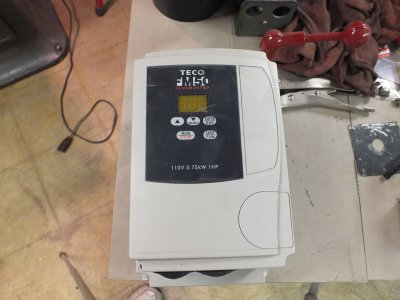

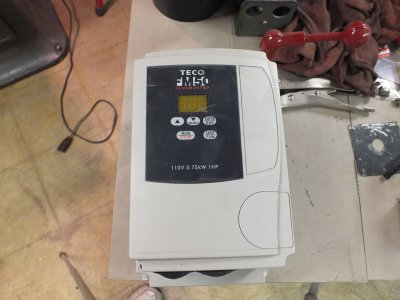

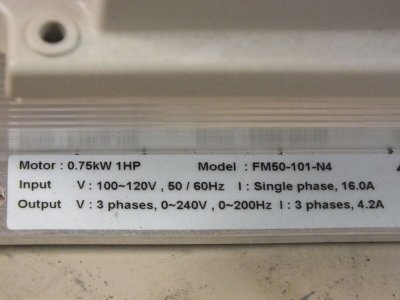

This is the vfd I chose, a teco, suitable for wet environments. If it's waterproof it will be dust proof, and that's a good thing since it's in my wood shop. Another cool thing about it is it has a built in cooling fan inside the enclosure and a huge heat sink. It can run an external speed pot as well, maybe I'll do that later. The board that I am mounting it to the wall with is open in the back for air flow and cooling. I spent a little more for this unit but I do not have to build an enclosure for it and spend the money to do so, or take the time to do so. 110v single phase in, 220v 3 phase out. rated for 1hp but my motor is only 3/4hp. good to have a little cushion I think. The wire is pulled to power the vfd, just gotta hook it up. I have to buy some shielded wire to run from the vfd to the switch and the motor.

This is the vfd I chose, a teco, suitable for wet environments. If it's waterproof it will be dust proof, and that's a good thing since it's in my wood shop. Another cool thing about it is it has a built in cooling fan inside the enclosure and a huge heat sink. It can run an external speed pot as well, maybe I'll do that later. The board that I am mounting it to the wall with is open in the back for air flow and cooling. I spent a little more for this unit but I do not have to build an enclosure for it and spend the money to do so, or take the time to do so. 110v single phase in, 220v 3 phase out. rated for 1hp but my motor is only 3/4hp. good to have a little cushion I think. The wire is pulled to power the vfd, just gotta hook it up. I have to buy some shielded wire to run from the vfd to the switch and the motor.

Last edited:

- Joined

- Jun 22, 2012

- Messages

- 1,552

I have cleaned up the switch and contacts, painted the cover, and made a new top plate for the switch. I am a truck driver for a metal rolling company and I travel to a lot of different kinds of fab and welding shops. One shop that I go to a lot has a laser, I showed them the top plat that the paint had worn off of and asked if they could make one for me, they did. Just plain steel laser cut and etched, will outlast me, I buffed it a little. Kinda neet and just one of those little things. I also picked up a new junction box to mount on the outside of the base pedestal for the wiring.

I have cleaned up the switch and contacts, painted the cover, and made a new top plate for the switch. I am a truck driver for a metal rolling company and I travel to a lot of different kinds of fab and welding shops. One shop that I go to a lot has a laser, I showed them the top plat that the paint had worn off of and asked if they could make one for me, they did. Just plain steel laser cut and etched, will outlast me, I buffed it a little. Kinda neet and just one of those little things. I also picked up a new junction box to mount on the outside of the base pedestal for the wiring.

Last edited:

- Joined

- Feb 2, 2013

- Messages

- 3,627

nice plate, the etching on the top looks good!

looks like you are ready to rock!

looks like you are ready to rock!

- Joined

- Jun 22, 2012

- Messages

- 1,552

Thanks Mike, almost ready. Tomorrow I have to install a new garage door opener as My old one gave up the ghost. Then I will make a list of the wire and other things I will need to finish the wiring of the vfd. I can't wait to get power to this thing and get it running, I hope all goes well with the vfd, rotary switch, and wiring. The Wire is already pulled from the breaker panel to the shop, just gotta connect everything up. Oh and I almost forgot, I gotta think about leveling it too.nice plate, the etching on the top looks good!

looks like you are ready to rock!

Greg.

That is a spiffy little switch plate .....very cool.

I've been using my H10 a little bit now and then for the last 6 months and its been fun. You will enjoy the little South Bend.

I have to laugh a bit in the way we seem to think. I too put a sheet metal back splash behind the lathe. Mine is much more crude -- made from Air Duct Return cut in half --- funny thing is it creates some little 4" wide shelfs to rest my oils and little stuff on. That aluminum plate is First Class all way!

The pics are when I finally positioned the lathe back in January. Making quite a few chips nowadays...... actually covered a bit with them right now!!:thumbsup:

That is a spiffy little switch plate .....very cool.

I've been using my H10 a little bit now and then for the last 6 months and its been fun. You will enjoy the little South Bend.

I have to laugh a bit in the way we seem to think. I too put a sheet metal back splash behind the lathe. Mine is much more crude -- made from Air Duct Return cut in half --- funny thing is it creates some little 4" wide shelfs to rest my oils and little stuff on. That aluminum plate is First Class all way!

The pics are when I finally positioned the lathe back in January. Making quite a few chips nowadays...... actually covered a bit with them right now!!:thumbsup:

- Joined

- Jan 11, 2013

- Messages

- 1,821

I have cleaned up the switch and contacts, painted the cover, and made a new top plate for the switch. I am a truck driver for a metal rolling company and I travel to a lot of different kinds of fab and welding shops. One shop that I go to a lot has a laser, I showed them the top plat that the paint had worn off of and asked if they could make one for me, they did. Just plain steel laser cut and etched, will outlast me, I buffed it a little. Kinda neet and just one of those little things. I also picked up a new junction box to mount on the outside of the base pedestal for the wiring.

View attachment 56516View attachment 56517View attachment 56518

Holy crap that is totally cool! Beautiful! Wow! You could sell those! Looks like a lot of work- I guess it's not really cost-effective

Great score man!

Bernie

- Joined

- Jan 11, 2013

- Messages

- 1,821

Greg.

That is a spiffy little switch plate .....very cool.

I've been using my H10 a little bit now and then for the last 6 months and its been fun. You will enjoy the little South Bend.

I have to laugh a bit in the way we seem to think. I too put a sheet metal back splash behind the lathe. Mine is much more crude -- made from Air Duct Return cut in half --- funny thing is it creates some little 4" wide shelfs to rest my oils and little stuff on. That aluminum plate is First Class all way!

The pics are when I finally positioned the lathe back in January. Making quite a few chips nowadays...... actually covered a bit with them right now!!:thumbsup:

Very pretty machine. I think yours may be the same era as mine, just a bench model and I have a floor model. Did you restore it to look so pretty?

Bernie

- Joined

- Dec 22, 2011

- Messages

- 715

Hi Greg,

One nice thing about painting in 100 degree weather, the paint flows well. )

)

Nice to see you're finally in the home stretch. That VFD looks very sweet. I've never used one of those four way tool holders. I think they could be handy, but the quick change is really a must in my opinion.

You have one great looking lathe!

Steve

One nice thing about painting in 100 degree weather, the paint flows well.

Nice to see you're finally in the home stretch. That VFD looks very sweet. I've never used one of those four way tool holders. I think they could be handy, but the quick change is really a must in my opinion.

You have one great looking lathe!

Steve