Greg, as a complete beginner to the world of the metalshop, just wanted to let you know what an inspiration your restoral has been to read through. Love to see things being given a new lease on life, and your attention to detail is outstanding. Fantastic job!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heavy 10 project

- Thread starter woodtickgreg

- Start date

- Joined

- Jun 22, 2012

- Messages

- 1,552

Greg, as a complete beginner to the world of the metalshop, just wanted to let you know what an inspiration your restoral has been to read through. Love to see things being given a new lease on life, and your attention to detail is outstanding. Fantastic job!

Steve, I'm glad you enjoyed my thread. I'm not a know it all and I learned a lot of things as I went along. I'm kinda a jack of all trades, master of none, LOL. If my work inspires others to do the same that's a good thing. It has been a very gratifying project that I am very proud of and I think others should do the same. These old machines are really very easy to work on if you take your time and do some research. I had some setbacks along the way, but nothing that couldn't be overcome. Thanks for the kind words, I really get a kick out of people enjoying my project.

- Joined

- Mar 10, 2012

- Messages

- 1,368

Greg, (or anyone else who'd know) when you did your compound rest did yours have a little brass shoe/plug with a set screw on the side of the rest? Like in this pic (not mine)?

(EDIT) I got my answer over on Yahoo. It's simply a brass plug so the set screw doesn't bugger up the gib.

(EDIT) I got my answer over on Yahoo. It's simply a brass plug so the set screw doesn't bugger up the gib.

Last edited:

- Joined

- Jun 22, 2012

- Messages

- 1,552

Greg, (or anyone else who'd know) when you did your compound rest did yours have a little brass shoe/plug with a set screw on the side of the rest? Like in this pic (not mine)?

(EDIT) I got my answer over on Yahoo. It's simply a brass plug so the set screw doesn't bugger up the gib.

Funny! Yup mine had that.

- Joined

- Feb 2, 2013

- Messages

- 3,628

:man:

Greg, YOU DA MAN!!!!!!

your presentation is excellent, the lathe is absolutely beautiful. perfectly detailed job in all aspects.

thanks again for the inspiration as well as your words of encouragement.

i'll be interested to see your VFD !

mike

Greg, YOU DA MAN!!!!!!

your presentation is excellent, the lathe is absolutely beautiful. perfectly detailed job in all aspects.

thanks again for the inspiration as well as your words of encouragement.

i'll be interested to see your VFD !

mike

- Joined

- Jan 2, 2011

- Messages

- 331

Just so you guys don't think that I have been slacking, I have been working on the lathe when I can. Work has been just insane lately since I got back, working a full time job and a part time job takes a lot out of me sometimes but I gotta take it when I can. Here's some pics of what I have gotten done so far. Started with a dirty apron assembly and stripped it for a trip to the parts washer to clean it with wire brushes for a better inspection of the parts. The sump had some chips in it as expected but not to bad. I have seen some guys sumps just packed with crud! Everything looked real good and no surprises so I wire wheeled all the paint off and buffed up the handles in preperation for painting. got everything all masked off too. I did get the first coat of paint on today, hope to have some more pics next weekend!

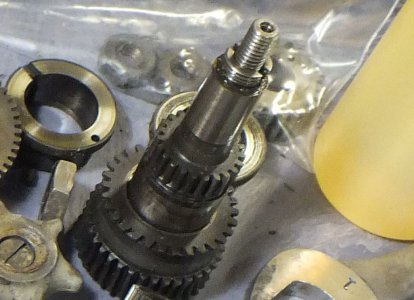

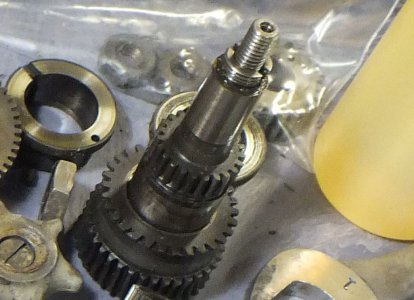

Greg, am I missing something, but was your clutch assembly different than the one in the Guide to Renovating book? Mine is like yours and appears to have no thrust bearings and bushing.. it has that thin gear too.. (?) maybe I have over looked something?

- Joined

- Jun 22, 2012

- Messages

- 1,552

A lot of my parts where not exactly as shown in the book, you will probably find this with yours too. I am trying to nremember but I think that thin gear was not actually a gear, but the oil slinger.Greg, am I missing something, but was your clutch assembly different than the one in the Guide to Renovating book? Mine is like yours and appears to have no thrust bearings and bushing.. it has that thin gear too.. (?) maybe I have over looked something?

View attachment 51070

Last edited:

- Joined

- Mar 10, 2012

- Messages

- 1,368

Greg, am I missing something, but was your clutch assembly different than the one in the Guide to Renovating book? Mine is like yours and appears to have no thrust bearings and bushing.. it has that thin gear too.. (?) maybe I have over looked something?

View attachment 51070

My 57 H10 didn't have the thrust bearing or bushing either. The toothed slim washer/gear is just what Greg said. It's simply an oil slinger to get oil around inside the apron. BTW, when reassembling the apron I kept the clutch tight so the inner splined gears would remain seated inside the clutch. If they come out of place you have to reopen the clutch to reseat them properly. It doesn't take more than 1-1/2 revolution of the knob/handle to loosen it up enough to where they'll move. That drove me nuts when I first finished the apron and tried to get everything back together only to find the clutch plates came out and moved around enough to not engage properly.

- Joined

- Jan 3, 2013

- Messages

- 78

To speed the stripping process use a gel stripper such as strippeze. Glop on a thick coat 1/8 or more thick in a small area 6 X 6 to 10 X 10 and quickly cover with Saran Wrap. Chemicals don't effect the Saran wrap. Lift an edge and overlap the applications. The volital solvents are trapped against the work. When application is complete all over, wait 2 hours. Start removing the wrap in the same approx. order as applied. As the wrap is lifted most of will stick to it. Immediatly wire brush the paint that is sticking to the machine and it will easily come off.

This reduces the fumes in the air as well.

This reduces the fumes in the air as well.