F

Firestopper

Forum Guest

Register Today

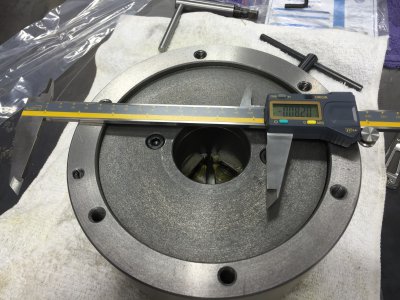

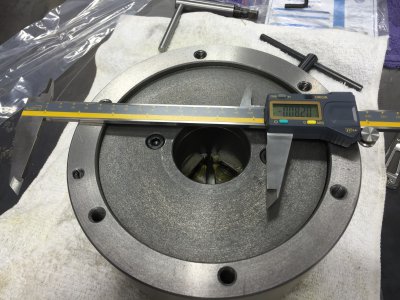

Got a new Igaging 12" caliper deliverd yesterday afternoon. I was waiting for this to turn the register on the new adaptor plate to mount the newly acquired Bison 8" 4-jaw scroll with fine adjustment. It required .082 reduction and took it in three passes. The chuck was a Smokin deal from member mksj and with his generosity I was able to upgrade.

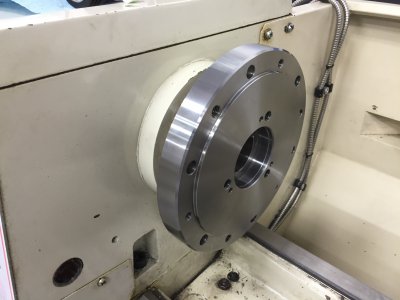

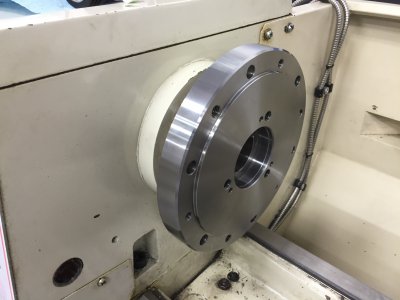

Amazing how quickly it can be dialed in with excellent repeatability. No vibration at any speed, nice and smooth. I placed adaptor plate in the freezer prior to assembling for a nice fit. Mark also presented me with two custom made mini T wrenches. The last photo shows a precision ground arbor I used to test the fine adjustment and got it to read .0000. Amazing upgrade IMO.

Amazing how quickly it can be dialed in with excellent repeatability. No vibration at any speed, nice and smooth. I placed adaptor plate in the freezer prior to assembling for a nice fit. Mark also presented me with two custom made mini T wrenches. The last photo shows a precision ground arbor I used to test the fine adjustment and got it to read .0000. Amazing upgrade IMO.