- Joined

- Feb 2, 2013

- Messages

- 3,627

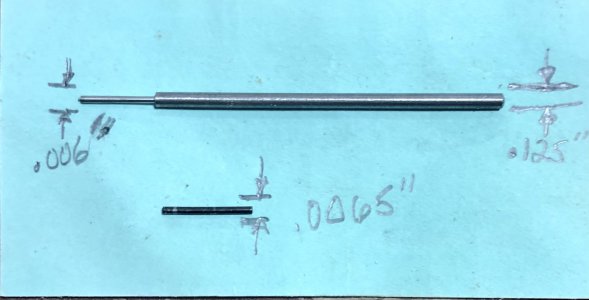

I'm working on a project that had the smallest pin (.065”) that required extraction, luckily through holes are present for the pin.

i went to the toolbox and looked for my smallest pin punch, the closest i came was a .30"

obviously, that's a no-go.

i searched through the crap and found a 1/8"x3"unknownium pin that had an end broken off

due to the scale of the work i employed the Unimat SL1000

i used the stock 3J chuck and extended about 3/4"

after squaring the end, the diameter was reduced to .060” in steps to a length of approximately 11/16".

i relieved the tip to help stay on the split pin while driving

the end result was quite nice

have a look....

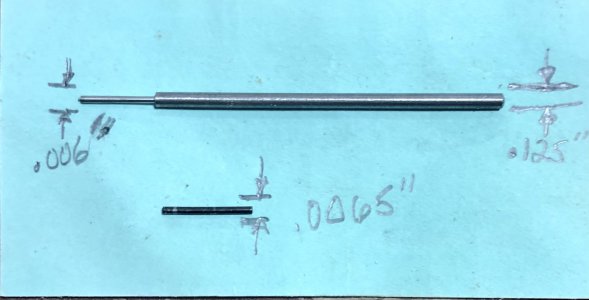

as you can see the pin punch worked, the offending pin is pictured below the punch.

thanks for reading!

I screwed up in my previous post, this has been edited due to stupidity on my part

The drawing is incorrect, I measured incorrectly, placing an extra decimal point of resolution where it should not be.

My sincere apologies for my mistake .

i went to the toolbox and looked for my smallest pin punch, the closest i came was a .30"

obviously, that's a no-go.

i searched through the crap and found a 1/8"x3"unknownium pin that had an end broken off

due to the scale of the work i employed the Unimat SL1000

i used the stock 3J chuck and extended about 3/4"

after squaring the end, the diameter was reduced to .060” in steps to a length of approximately 11/16".

i relieved the tip to help stay on the split pin while driving

the end result was quite nice

have a look....

as you can see the pin punch worked, the offending pin is pictured below the punch.

thanks for reading!

I screwed up in my previous post, this has been edited due to stupidity on my part

The drawing is incorrect, I measured incorrectly, placing an extra decimal point of resolution where it should not be.

My sincere apologies for my mistake .

Last edited: