While practicing 0.002 cuts on a 3/4" -10 thread, I noticed the lead screw slipping. The head had back gears engaged and the slowest speed. I removed the lead screw and collar on the quick change gear box. The key in the collar was in good shape. The keyway in the screw was excellent. Putting a wrench on the collar and one on the screw, the keyed insert inside the collar will slip with moderate pressure. This may be by design so damage to the qcgb is avoided if the carriage hangs up. My questions are: 1. Is this keyed insert in the collar supposed to slip? 2. Is there a service manual available for the carriage to check gears, clearances and tolerances?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE MAIN DISCUSSION SECTION

- ALL ABOUT MACHINE RESTORATION & WAY SCRAPING

- ++ MACHINE RESTORATION NOTEWORTHY THREADS ++

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

10F lead screw slips

- Thread starter HaroldT

- Start date

- Joined

- Dec 3, 2017

- Messages

- 1,909

I bet someone will be along with an answer. But if you could provide some pictures of the collar and where it goes, I’d appreciate it. I have a 10F, and don’t remember a collar anywhere on it, with regard to the leadscrew.

I think the newer ones had a collar with a shear pin in them. But I thought that was specific to the Atlas Craftsman branded machines of maybe the 60’s.

I think the newer ones had a collar with a shear pin in them. But I thought that was specific to the Atlas Craftsman branded machines of maybe the 60’s.

- Joined

- Apr 30, 2015

- Messages

- 11,309

I think maybe your shear pin has already sheared? Some later 12" Atlas's have a friction clutch system for the leadscrew

but I was not aware of one for the 10s

but I was not aware of one for the 10s

This is a familiar problem. I had a well worn 10F about 20yrs back with the same issue. It turned out it had several other problems.

Back to the question... that keyed collar is not supposed to slip.

On mine, the leadscrew bearing block washer was worn. The leadscrew moved left to right a bit. I kludged a fix by shimming the leadscrew right bearing block forcing the leadscrew into the collar, plus using some aircraft epoxy/glue. It only worked for a year or two. Finally, I drilled the collar/screw to install a tapered pin. The box assembly didn't like it, although it did work.

The pin solved that problem, only to unveil many others in the box (rabbit hole). You can make the box operate better if you want to invest a bunch of time and shim stock. I don't think those lathes could hold 0.003 out of the factory. I was happy to get 0.010.

I don't know about a service manual. 'Vintage Machinery' has some Atlas manuals available to download.

Back to the question... that keyed collar is not supposed to slip.

On mine, the leadscrew bearing block washer was worn. The leadscrew moved left to right a bit. I kludged a fix by shimming the leadscrew right bearing block forcing the leadscrew into the collar, plus using some aircraft epoxy/glue. It only worked for a year or two. Finally, I drilled the collar/screw to install a tapered pin. The box assembly didn't like it, although it did work.

The pin solved that problem, only to unveil many others in the box (rabbit hole). You can make the box operate better if you want to invest a bunch of time and shim stock. I don't think those lathes could hold 0.003 out of the factory. I was happy to get 0.010.

I don't know about a service manual. 'Vintage Machinery' has some Atlas manuals available to download.

- Joined

- Jan 28, 2011

- Messages

- 3,485

They are no spring chicken. They have not been made in decades and like any other American machine from that time, they need some TLC.

They will hold whatever tolerance required. I did a lot of rifle work on mine. I did have to repair and renew like the leadscrew. Once all the slop is taken out of the system these lathe work just fine.

They will hold whatever tolerance required. I did a lot of rifle work on mine. I did have to repair and renew like the leadscrew. Once all the slop is taken out of the system these lathe work just fine.

To jwmay, This collar is the first piece the lead screw goes into on the quick change gearbox. It is held onto the gearbox shaft with two set screws. The white mark on the face at 7 o'clock was aligned with the key showing at 3 o'clock.

On pdentrem's picture above it is the collar showing between the gearbox and the lead screw. My lead screw has no slop in any direction and the teeth a and keyway are still square. Gear tolerances are good.

To markba633, This one actually has a key, not a shear pin.

To garymzz, I considered a taper pin but not easily repairable. I am thinking of drilling two holes for set screws to about 1/3 the thickness of the keyed insert, pressing out the insert and tapping the collar. Then I will put the insert into the freezer and heat the collar in a sonic cleaner at 50 deg C to minimize damage during reassemble. Also considered knurling, but..... nah.

On pdentrem's picture above it is the collar showing between the gearbox and the lead screw. My lead screw has no slop in any direction and the teeth a and keyway are still square. Gear tolerances are good.

To markba633, This one actually has a key, not a shear pin.

To garymzz, I considered a taper pin but not easily repairable. I am thinking of drilling two holes for set screws to about 1/3 the thickness of the keyed insert, pressing out the insert and tapping the collar. Then I will put the insert into the freezer and heat the collar in a sonic cleaner at 50 deg C to minimize damage during reassemble. Also considered knurling, but..... nah.

Attachments

- Joined

- Dec 3, 2017

- Messages

- 1,909

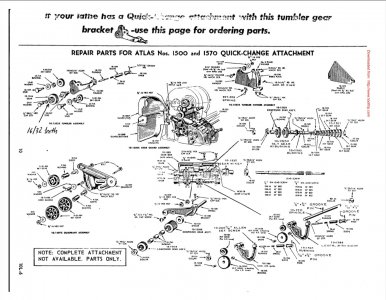

Part number 10-253?

Sorry, I don’t think I can answer your questions. I’m gonna bow out and let the experts handle it. But I’ll stay tuned in case I need to know it someday.

When I installed the qcgb, I don’t remember ever having any of that apart. I slid the leadscrew in and bolted the carrier on the tailstock end. Presumably I tightened the set screw on that collar, but the years have erased that data from my hard drive.

Sorry, I don’t think I can answer your questions. I’m gonna bow out and let the experts handle it. But I’ll stay tuned in case I need to know it someday.

When I installed the qcgb, I don’t remember ever having any of that apart. I slid the leadscrew in and bolted the carrier on the tailstock end. Presumably I tightened the set screw on that collar, but the years have erased that data from my hard drive.

Last edited:

- Joined

- Jan 25, 2015

- Messages

- 2,558

Meh, I can get 0.001 to 0.002 on my 10F without trying too hard.

Just have to know how to work the machine. Theres more to it than looking at a dial and running the carriage…and the older/more worn the machine, the better you have to “know“ it.

Things were measurably easier after I rebuilt it though. Pretty standard behavior for worn machines.

Just have to know how to work the machine. Theres more to it than looking at a dial and running the carriage…and the older/more worn the machine, the better you have to “know“ it.

Things were measurably easier after I rebuilt it though. Pretty standard behavior for worn machines.

You are right, you normally wouldn't have to mess with it, just slide the lead screw in and go. I took it off to see why it was slipping.Part number 10-253?

Sorry, I don’t think I can answer your questions. I’m gonna bow out and let the experts handle it. But I’ll stay tuned in case I need to know it someday.

When I installed the qcgb, I don’t remember ever having any of that apart. I slid the leadscrew in and bolted the carrier on the tailstock end. Presumably I tightened the set screw on that collar, but the years have erased that data from my hard drive.