- Joined

- Jun 12, 2014

- Messages

- 4,824

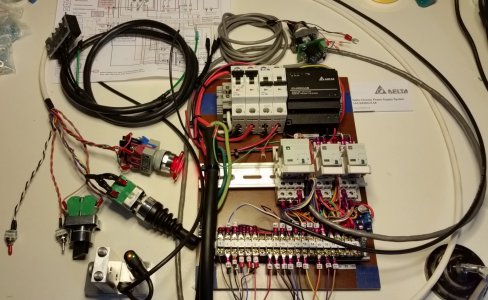

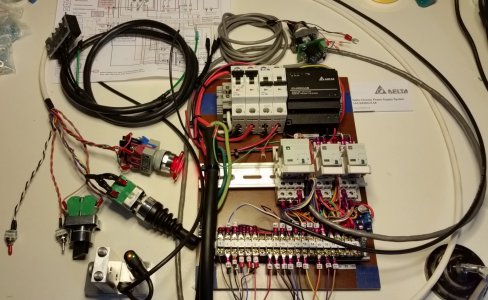

VFD system build on the bench being tested, still waiting for a contactor for the coolant circuit. Have done a number of different VFD systems from very simple to more complex, this is both high voltage and VFD logic system, includes everything but the VFD. The newer designs I use on these systems is not dependent on the VFD power supply to operate the relays, so more applicable to a wider range of VFDs. This level of design/complexity is more applicable to lathes where a number of different VFD functions are used, other designs can be much simpler This system has provisions for both 12 and 24VDC output so can drive tachs, lights, solenoids, etc. This system includes Jog joystick which will only operate when the machine is stopped, variable braking, proximity system with safety lock switch and P bypass switch, and coolant system contactor (to be installed) that runs only when the the for/rev relays are activated. A number of safety interlocks, and rapid braking if any of these are tripped, the VFD will also be wired to the foot brake. Many different ways to build these VFD systems, this one was a little different so posting. Anyone interested in a schematic design or parts list, let me know.