- Joined

- Sep 28, 2013

- Messages

- 4,308

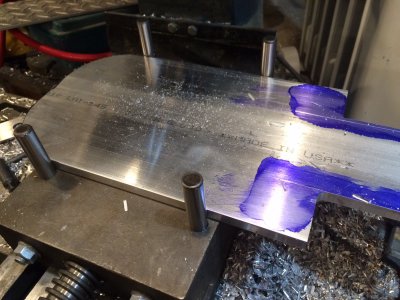

finally finished making a temporary spindle pulley for my Atlas 618. Some previous owner had rebushed the 4 step spindle pulley and hashed it up - the bore was both oversized and not concentric to the pulley faces - so it caused a lot of vibration especially in direct drive. However, I only have one lathe (I know I know, I'll have to fix that) so to remove the duff bushings, fit the new ones and bore them to size I needed a way to drive the spindle.

Made this from a large chunk of 2in alu round. Cut the step, then plunged the center of the V with my parting tool and did the sides with my 60deg threading tool. Not 100% the right angle, but it'll do. Then cut part of the way through with my parting tool while the end was still supported with the live center. Removed the live center, drilled to 11/16 (I think) and bored to the finish size of 0.787, 2 thou over the spindle diameter. Then drilled and tapped for 10-24 set screws.

Pulled all the stuff off the spindle and this slipped on just right. Spun freely but without any noticeable radial play, which I was well pleased with. Also gives me good target dimensions for the new bushing ID. Put a piece of lead solder under each set screw and tightened it down - doesn't seem to move from ~500 to 1500rpm, but we'll see how it does under load. Now I'll have to dig out the bushings I have and start working on a plan to get the old ones out and the new ones in! Given that this took me 3 weeks, I expect this'll be done by March sometime!

Made this from a large chunk of 2in alu round. Cut the step, then plunged the center of the V with my parting tool and did the sides with my 60deg threading tool. Not 100% the right angle, but it'll do. Then cut part of the way through with my parting tool while the end was still supported with the live center. Removed the live center, drilled to 11/16 (I think) and bored to the finish size of 0.787, 2 thou over the spindle diameter. Then drilled and tapped for 10-24 set screws.

Pulled all the stuff off the spindle and this slipped on just right. Spun freely but without any noticeable radial play, which I was well pleased with. Also gives me good target dimensions for the new bushing ID. Put a piece of lead solder under each set screw and tightened it down - doesn't seem to move from ~500 to 1500rpm, but we'll see how it does under load. Now I'll have to dig out the bushings I have and start working on a plan to get the old ones out and the new ones in! Given that this took me 3 weeks, I expect this'll be done by March sometime!