- Joined

- Nov 23, 2014

- Messages

- 2,610

POTD was to make a small work table for my Roper Whitney #218 punch press. I have a 24” x 24” work table, but it has a lot of overhang toward the front which makes it hard to get your face right up to the punch and work. Must be my 57-year old eyesight or something . . .

Happened to have a 9” x 9” piece of 1/8” aluminum plate in the scrap bin. Plan was to bore a hole in the aluminum which would fit over an outer ring in the punch press die holder. The table would fasten to the die holder with three ¼”-20 flat head cap screws.

Had to brush up a little on my trig. Almost embarrassing to admit it, but I struggled a bit remembering how to calculate the radius of a circle when all you know is the distance between legs of an equilateral triangle on the circle. The die holder mounting screws don’t go all the way through the holder, so I couldn’t use a transfer punch to mark the screw holes.

Finally figured out the formula was “R = (0.5 * leg length) / cos 30 deg.”. Boy, my old trig teacher would have rolled her eyes at the sweat beads I had trying to remember how to calculate R . . .

Why did I need the radius of the mounting holes? Gotta love a DRO with a PCD (holes on a circle) function! The function is great; set the spindle on the circle center, tell the DRO the diameter of the circle, starting angle, ending angle and number of holes and off you go.

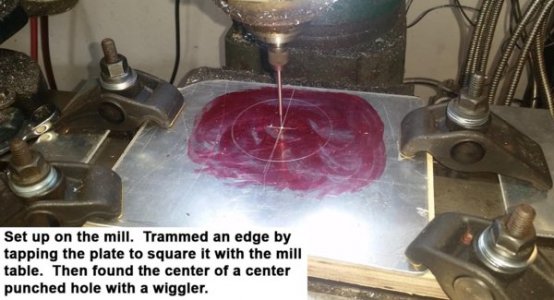

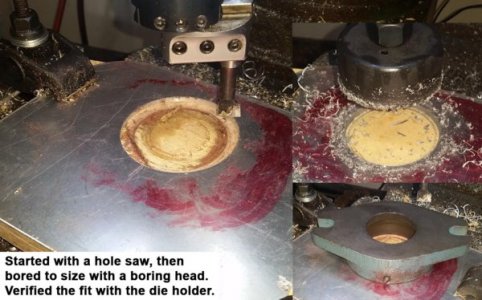

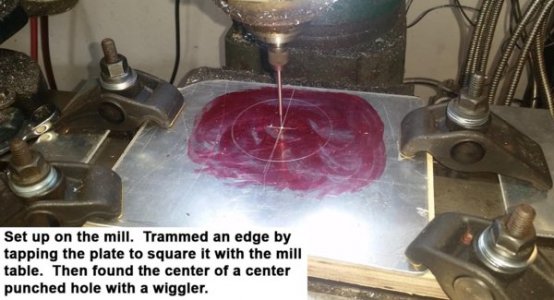

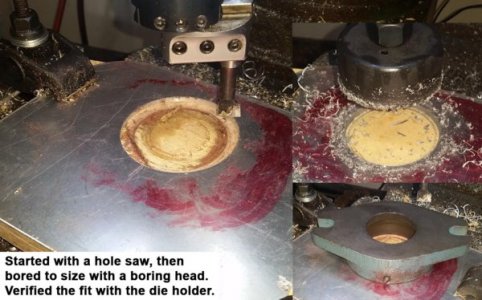

The aluminum plate was set on a sheet of ¾” plywood on the mill table. Trammed in the top edge to parallel with the X-axis of the mill table. Then found a center punched hole with a wiggler. Started with a 2 ½” hole saw through the aluminum plate. Then opened the hole to the necessary 3.010” to fit over the die holder.

Then went to the mill DRO’s PCD function. The first hole was at 90 deg., I usually make the starting and ending angle the same and add one to the number of holes. In this case, starting and ending were 90 deg. with 4 holes. I add one to the number of holes because the starting and ending points are on the same spot and count as 2 holes.

Well, it didn’t work out. My problem was starting at 90 and ending at 90. I should have entered 90 and 450 (90 + 360). I ended up just doing the math by starting at 90 and ending at 330 with 3 holes. Drilled and countersunk the holes on the mill.

Set the table on the die holder and the holes lined up perfectly. Only problem I ran into at that point was the thickness of the table (1/8”) isn’t thick enough to have the ¼” flat head screws flush with the table and have the table tight to the die holder. Couple of washers underneath the table for each screw remedied that problem.

Bruce

Happened to have a 9” x 9” piece of 1/8” aluminum plate in the scrap bin. Plan was to bore a hole in the aluminum which would fit over an outer ring in the punch press die holder. The table would fasten to the die holder with three ¼”-20 flat head cap screws.

Had to brush up a little on my trig. Almost embarrassing to admit it, but I struggled a bit remembering how to calculate the radius of a circle when all you know is the distance between legs of an equilateral triangle on the circle. The die holder mounting screws don’t go all the way through the holder, so I couldn’t use a transfer punch to mark the screw holes.

Finally figured out the formula was “R = (0.5 * leg length) / cos 30 deg.”. Boy, my old trig teacher would have rolled her eyes at the sweat beads I had trying to remember how to calculate R . . .

Why did I need the radius of the mounting holes? Gotta love a DRO with a PCD (holes on a circle) function! The function is great; set the spindle on the circle center, tell the DRO the diameter of the circle, starting angle, ending angle and number of holes and off you go.

The aluminum plate was set on a sheet of ¾” plywood on the mill table. Trammed in the top edge to parallel with the X-axis of the mill table. Then found a center punched hole with a wiggler. Started with a 2 ½” hole saw through the aluminum plate. Then opened the hole to the necessary 3.010” to fit over the die holder.

Then went to the mill DRO’s PCD function. The first hole was at 90 deg., I usually make the starting and ending angle the same and add one to the number of holes. In this case, starting and ending were 90 deg. with 4 holes. I add one to the number of holes because the starting and ending points are on the same spot and count as 2 holes.

Well, it didn’t work out. My problem was starting at 90 and ending at 90. I should have entered 90 and 450 (90 + 360). I ended up just doing the math by starting at 90 and ending at 330 with 3 holes. Drilled and countersunk the holes on the mill.

Set the table on the die holder and the holes lined up perfectly. Only problem I ran into at that point was the thickness of the table (1/8”) isn’t thick enough to have the ¼” flat head screws flush with the table and have the table tight to the die holder. Couple of washers underneath the table for each screw remedied that problem.

Bruce