Spent part of today doing maintenance on some equipment for work, and once again, I was totally annoyed that Arien's cheaped out to save a few pennies and used an extension on the engine's oil drain port so it ends just before it reaches the edge of the frame of the Power Brush it is mounted on. So, every oil change, I can get most of the oil to go through a funnel, but a fair amount always gets on the frame and it's a pain to clean it all up, and then the area gets a nice coating of dirt that just sticks there.

Today, I finally decided to make a slightly longer extension, which should prevent this from happening anymore.

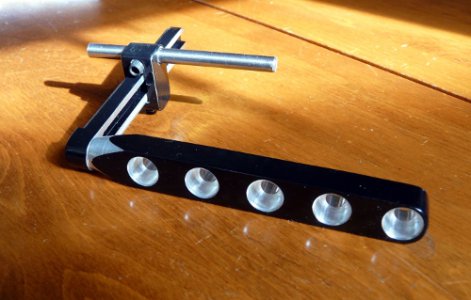

Pic of the old and new one, side by side:

New one, installed on the machine:

And, in the foreground of that pic, you can see a washer brazed to the head of a bolt. My dad came up with doing that, as that black part is the belt cover, and you regularly have to take it off to check out the belts. And doing that with gloves/mitts on in the winter sucks when you have to use a wrench or even a ratchet to do it, as the bolt is small and long. With the washer, it's easy to do with mitts on. We've done this for all the snowblowers as well (again, it saves Ariens a couple pennies per machine, but is a pain for everyone who buys one).

But they are also the geniuses who state that, as part of maintenance, if you can hear the u-joint between the engine and the power brush (necessary so you can angle the brush left and right), you should grease it. Fine. Except it only turns when the engine is running and the power brush is engages. If you can hear that u-joint over both the engine and the brushes, it needs to be replaced, as it will be seriously damaged...

Finally, a shot of what could very well be the ugliest 17mm hex head in the world. This is what you get when you freehand it on a bench grinder in a couple minutes:

And I'm sorry for disappointing everyone, as I used a tap and die for the threads at each end instead of single-pointing them on the lathe. I did use the lathe for turning the one end down to size and for drilling the through-hole...

Today, I finally decided to make a slightly longer extension, which should prevent this from happening anymore.

Pic of the old and new one, side by side:

New one, installed on the machine:

And, in the foreground of that pic, you can see a washer brazed to the head of a bolt. My dad came up with doing that, as that black part is the belt cover, and you regularly have to take it off to check out the belts. And doing that with gloves/mitts on in the winter sucks when you have to use a wrench or even a ratchet to do it, as the bolt is small and long. With the washer, it's easy to do with mitts on. We've done this for all the snowblowers as well (again, it saves Ariens a couple pennies per machine, but is a pain for everyone who buys one).

But they are also the geniuses who state that, as part of maintenance, if you can hear the u-joint between the engine and the power brush (necessary so you can angle the brush left and right), you should grease it. Fine. Except it only turns when the engine is running and the power brush is engages. If you can hear that u-joint over both the engine and the brushes, it needs to be replaced, as it will be seriously damaged...

Finally, a shot of what could very well be the ugliest 17mm hex head in the world. This is what you get when you freehand it on a bench grinder in a couple minutes:

And I'm sorry for disappointing everyone, as I used a tap and die for the threads at each end instead of single-pointing them on the lathe. I did use the lathe for turning the one end down to size and for drilling the through-hole...

Last edited: