Here is the thing I made.

Its purpose is to position a 3-D camera so it can rotate 360º around the subject's outstretched arm to document upper arm flab.

The client is a skin product testing lab. It is of my design. They told me what it needed to do and I figured out how to do it.

The base is made of Baltic Birch plywood and painted with spray pickumup truck bed coating. That stuff is great. It covers well, needs no priming and is tough as nails.

the original idea was to weld the joints, but I wasn't up to it. It is 16 ga. aluminum square tube. I practiced for hours but couldn't manage two successful welds in a row. I think the problem was the thin edge end of one tube butting against the side of another. The corner made that piece thicker and more of a heat sink. I couldn't get past the difference in thickness. Try as I might, I couldn't make the puddle go down the seams. Hot enough to puddle the side melted the end away.

So, I resorted to plan B, attatch the tubes with joints and hardware. A detail of the noodley elbow joint. This took a long time to make.

All those holes at all those positions and angles were difficult to clamp tight and square, and drill. Clamping and drilling it under the head of the mill was complicated and tedious.

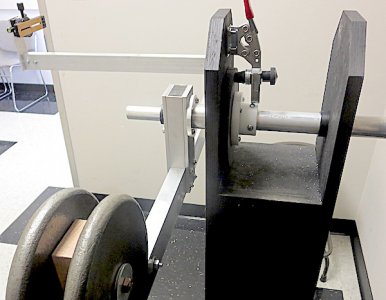

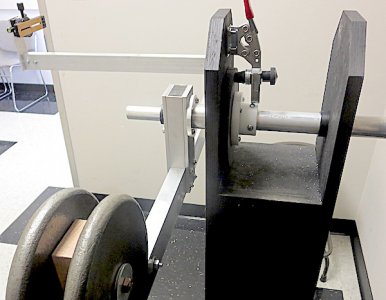

The hub and counter weights so the arm would balance with the weight of the 3-D camera. It has a disk break and clamp to hold position attached by a T-bushing of delrin-like plastic.

The USB cable from the camera passes through the axle shaft so it won't wrap around the axle.

The hub was equally tedious to make with a flange, section of square tube and two .25 x 2" straps. Welding would have been so much easier and faster. The weights are mounted on an oak angle attached with a 5/8" bolt, fender washers, and 1 inch bushings

This is a detail of the camera mount. A couple of arka clamp mounts so the camera can adjust forward and back, and a Panoramic swivel so it can swivel. It focuses with two laser dots that converge. Upper arms aren't cylindrical or symetrical, so the camera has to move in and out and rotate to compensate and keep the dots in the center of the upper people arms. Each image requires at least 4 images from 4 angles. That's why the 3D camera has to travel around the arms.

The raw camera images are fed into a computer which assembles them to make a virtual arm that can be twisted and turned and viewed from all angles.

This project took a week to concept, make plan drawings and complete. I vastly under bid the job and had to live with my estimate.