Hi John

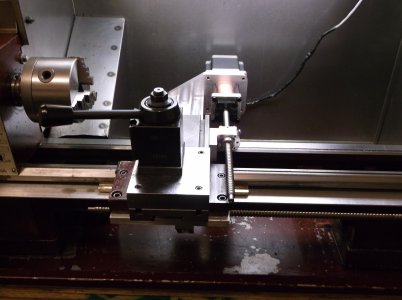

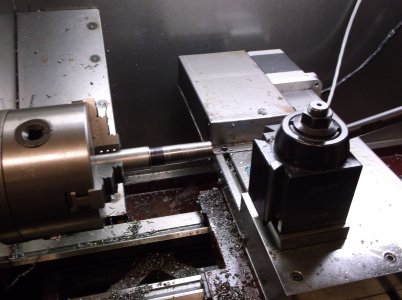

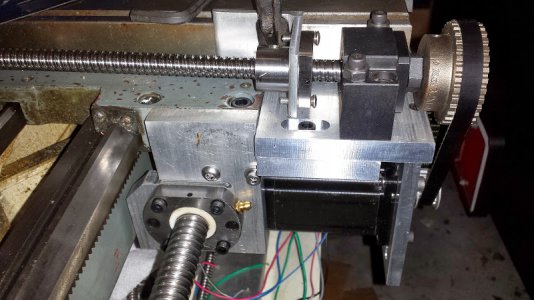

the extension I made to mount the motor on the rear is 4.5" long then there is a 1/2" plate extending to the right to mount the motor.

so the motor face is 5" beyond the end of the saddle.

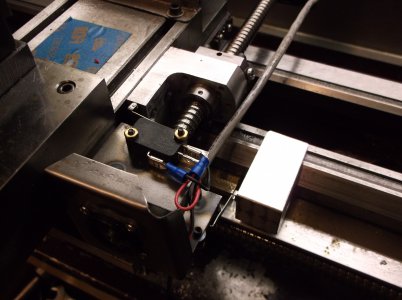

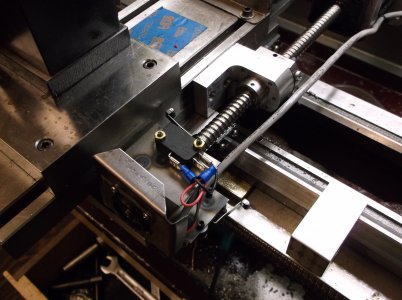

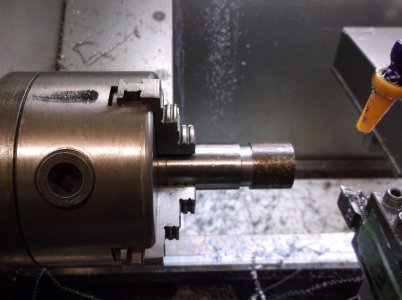

I had a problem with ball-screw wobble and I had a bit of work to nullify the problem. my lathe saddle was worn and the v grove wear would let the saddle twist when changing z direction. I turned the saddle upside down on the mill table, placed a 1/2" rod in the v groove and measured down to the table. then I measured the flat area the saddle rides on in the rear to the table. I wrote down the difference between the 2. I then mounted the saddle square to the mill table at a 45 degree angle and recut the v groove with a 3/4 end mill. once the groove was redone I placed the saddle back on the mill table used the 1/2" rod in the v groove and slowly took the rear flat surface down until the difference matched what I had measured before. now the saddle traveled square and flat again. I made new brass full length gibbs for the front and rear. the original front one was short because the rear part was a lock plate to lock the z axis. I didn't need the lock now so I made the gibb full length.

I tried at first to mount the motor at the spindle end and it was to close to the saddle, the imperfections in the screw would show up in the surface finish. I moved the z axis motor to the far end and didn't support both ends of the screw, just the motor end with a thrust bearing and coupling. that resolved all the finish problems and is plenty ridged to push and pull the saddle with only .0015 backlash.

I did all this testing before I had redone the saddle and it wasn't going to work until the saddle was redone. my v grove was just too worn to change z direction without pulling the saddle out of alignment.

I went back through the thread, I can't believe I didn't post about re-doing the saddle groove and gibbs. I'm going to see if I took pics but forgot to post them.

steve