I am still in the process of making fixtures for the T&C grinder. Building the grinder is only half the project. You then need various fixtures to properly present the work to the grinding wheel. It is hard to decide which ones to make first , so I am making them as I need them.

I now need a work head to hold end mills while sharpening the ends of the end mill. I could put them in the air bearing and change the wheel angle for every cut. But then I have to line up the wheel again to grind tools. Having an easily adjusted work head would be less setting up and much faster. I am starting with the spindle because by making it first , I can bore the head to fit the spindle. This is easier. If I bore the head to 1.625" like I want , I have to hit the spindle dimension and there are about 5 hours in making this spindle. I would hate to mess it up and start over ( besides , I only have enough material to make it once).

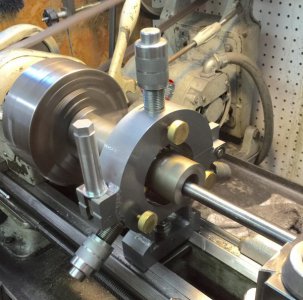

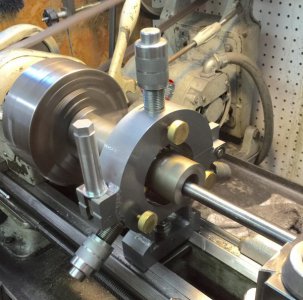

I used my new steady rest to hold the spindle steady while I bore it.

I used my new steady rest to hold the spindle steady while I bore it.

I bore to 1.252" for a nice slip fit on a 5C collet. I also cut the 10 degree angle for the collet. I finished th OD for about 1 1/2" on the end.

I bore to 1.252" for a nice slip fit on a 5C collet. I also cut the 10 degree angle for the collet. I finished th OD for about 1 1/2" on the end.

By doing all this in the same setup, I know everything is concentric.

By doing all this in the same setup, I know everything is concentric.

I chucked the finished end in the 4 jaw chuck , indicated within .0005" and put a center in the other end to turn the spindle OD.

I chucked the finished end in the 4 jaw chuck , indicated within .0005" and put a center in the other end to turn the spindle OD.

I made a center plug from a piece of aluminum to support this end.

I made a center plug from a piece of aluminum to support this end.

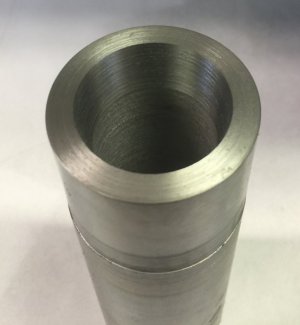

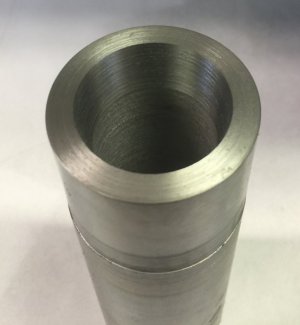

This is the finished spindle. I was having trouble getting a decent finish on this mystery metal and wound up .008" smaller than intended.

This is the finished spindle. I was having trouble getting a decent finish on this mystery metal and wound up .008" smaller than intended.  THAT is why I made the spindle first. Boring the body to fit is easy, but I could still screw it up

THAT is why I made the spindle first. Boring the body to fit is easy, but I could still screw it up  .

.

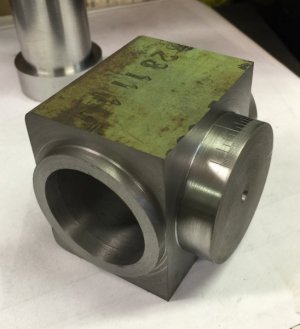

This chunk of cast iron wil transform into the work head body.

This chunk of cast iron wil transform into the work head body.

I now need a work head to hold end mills while sharpening the ends of the end mill. I could put them in the air bearing and change the wheel angle for every cut. But then I have to line up the wheel again to grind tools. Having an easily adjusted work head would be less setting up and much faster. I am starting with the spindle because by making it first , I can bore the head to fit the spindle. This is easier. If I bore the head to 1.625" like I want , I have to hit the spindle dimension and there are about 5 hours in making this spindle. I would hate to mess it up and start over ( besides , I only have enough material to make it once).

I used my new steady rest to hold the spindle steady while I bore it.

I used my new steady rest to hold the spindle steady while I bore it. I bore to 1.252" for a nice slip fit on a 5C collet. I also cut the 10 degree angle for the collet. I finished th OD for about 1 1/2" on the end.

I bore to 1.252" for a nice slip fit on a 5C collet. I also cut the 10 degree angle for the collet. I finished th OD for about 1 1/2" on the end. By doing all this in the same setup, I know everything is concentric.

By doing all this in the same setup, I know everything is concentric. I chucked the finished end in the 4 jaw chuck , indicated within .0005" and put a center in the other end to turn the spindle OD.

I chucked the finished end in the 4 jaw chuck , indicated within .0005" and put a center in the other end to turn the spindle OD. I made a center plug from a piece of aluminum to support this end.

I made a center plug from a piece of aluminum to support this end. This is the finished spindle. I was having trouble getting a decent finish on this mystery metal and wound up .008" smaller than intended.

This is the finished spindle. I was having trouble getting a decent finish on this mystery metal and wound up .008" smaller than intended.  .

. This chunk of cast iron wil transform into the work head body.

This chunk of cast iron wil transform into the work head body.