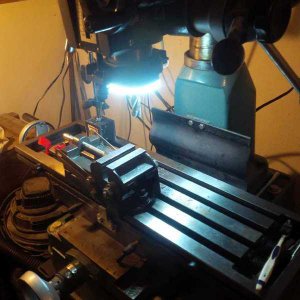

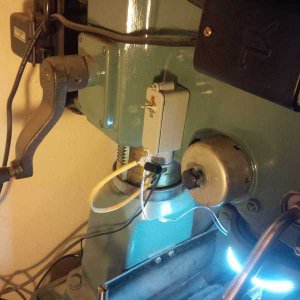

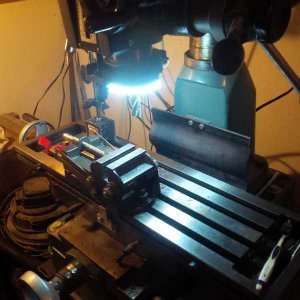

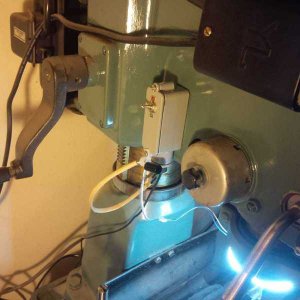

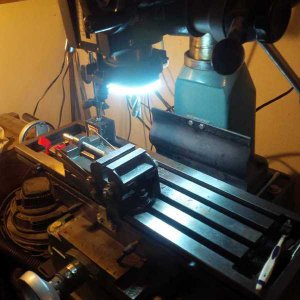

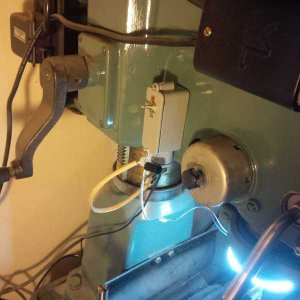

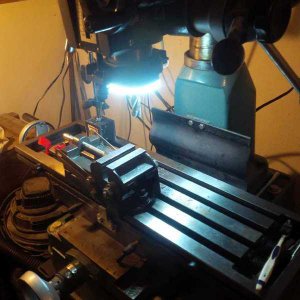

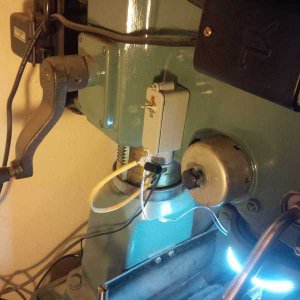

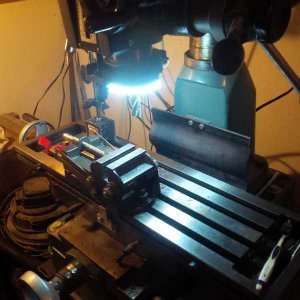

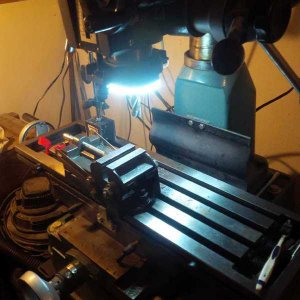

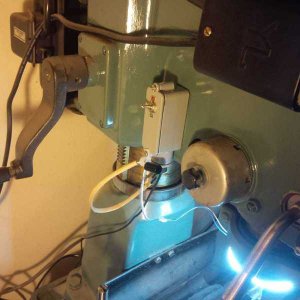

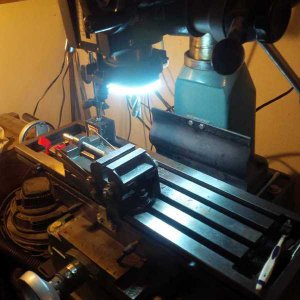

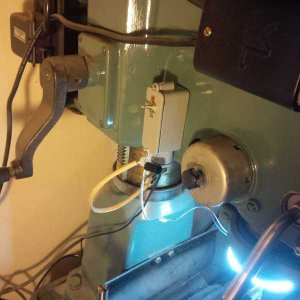

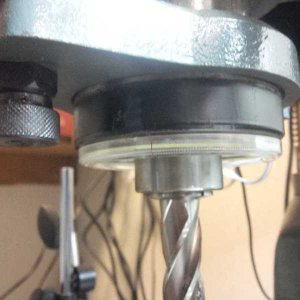

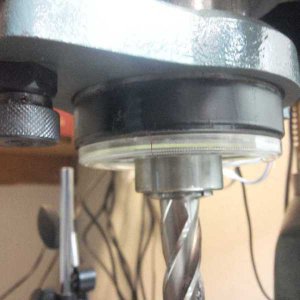

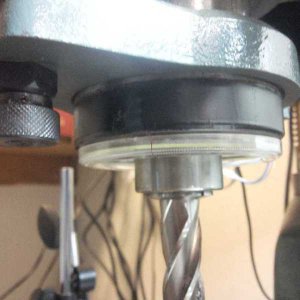

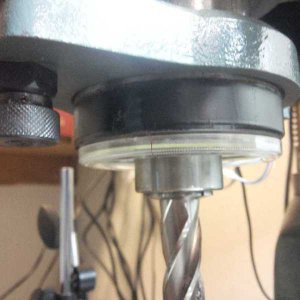

After seeing what some of you have done with an angel eye, I ordered one for my RF30 (about $9.00 delivered from ebay). I made a simple switch box from a PVC connection box and used a leftover 18v computer power supply (the LEDs run on 12 - 24v). The switch box was attached to the side of the head with double sided tape, the power supply box was attached to the back of the mill base with the same tape. I'm amazed how well it works, plenty of light focused right down where I need it. I couldn't be more pleased, and it cost under $15 for everything!