- Joined

- May 2, 2021

- Messages

- 330

So about the story...At the price you are getting this for, your gas to go get it. Renting a trailer and a fork lift once you get home would still be a cheap option with this unit.

If I might ask, how did the owner of the mill come to make this offer? Did you advertise for a mill? You indicate that it is a 1.5 hour drive, so I assume it is someone you may not know.

Thanks

I had just watched a well known YouTuber yesterday who was offered a Bridgeport.

Looked like you could serve dinner off it.

The ways were unscathed and chromed.

The paint was perfect.

The aluminum was all aluminumy and pretty.

And it operated as smooth as glass.

And I thought to myself. Self: why does this never happen to you?

And as I closed the video, one of the many alerts popped up - and this one was for some scrap sheet metal.

Only at the bottom of the add, it said: "and I also have a mill you can have if you have a big trailer"

So I immediately hit respond, and asked - exactly what kind of mill is this thing I can have?

And he said: "An old Webb. CNC".

Until today - that is what I knew about it.

So this morning - I brewed myself a coffee and drove 1.5 hours to see a man about a mill...

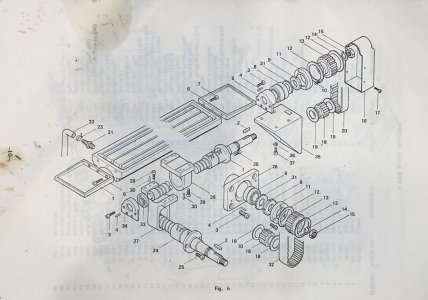

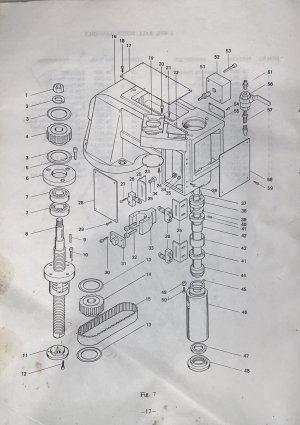

Pictures above tell the rest of the story.

They restore helicopters - and had decided they needed it out of the way.

It had apparently sat in the corner of the shop for a decade.

So it just kinda fell to me - though as these things go - until its in the garage - you never know.

I'm thinking through what I could do to best suit my needs.

I'm hungry to have a working mill - that's where this whole thing started before I found myself in a parking lot with old helicopters.

Some options I'm pondering:

1. Strip off the CNC. Turn it in to a manual. Hey - I got it for free! Put on a DRO and an X axis feed. Maybe put a potentiometer on the existing quill feed and use that as a power quill with no handle (cause I don't know how I would put on a handle.). Perhaps even tear it down, scrub it, paint it my favorite color of green, polish up the aluminum and steel bits. Have a compact 4000lb garage manual milling machine.

2. Put a battery in it, tell the computer where the parameters are (hey computer - they are over here! everything is ok!) maybe even skip the paint part, and figure out how to use it.

3. Take it modern. New servos motors, controller, some kinda screen, etc. etc.

Any thoughts on above?

The lower electrical cabinet is just the heavy power handling stuff, not the control electronics.

The lower electrical cabinet is just the heavy power handling stuff, not the control electronics.