-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aluminum Anodizing Needed

- Thread starter lesrhorer

- Start date

- Joined

- Jan 7, 2016

- Messages

- 3,279

I don't do anodizing, but I have recently tested some Cerakote at work. You may want to consider that.

The wear resistance of the oven-cured Cerakote was on par, if not better, than that of hard anodizing.

The wear resistance of the oven-cured Cerakote was on par, if not better, than that of hard anodizing.

- Joined

- Dec 10, 2023

- Messages

- 77

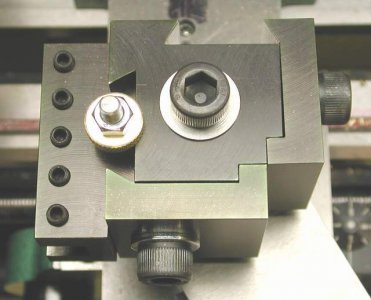

Anodizing can be done in your shop/at home. Pretty simple to do, just takes some water bath containers (ice bath & acid bath), car battery charger, battery (sulfuric) acid, lead probe and misc. I did this in 2001 for a small sized QCTP for a minilathe I had at the time (there weren't any smaller than AXA available at the time). Used 7075 T6 Alum., machined the parts on a minimill and did the anodizing in my driveway. Used Rit black dye for the color. To seal the pores to trap the dye, the anodized, dyed parts are boiled in water as the last step. Found instructions online but haven't looked recently. Only real issue was disposing of the acid afterward, but there are places/ways to do that.

I also did it with some specialty brackets I made for a surveying project, mounting a water velocity reading meter on the surveyor's prism rod for recording locations of water velocity readings as input to a digital elevation model as part of 3D hydraulic modeling of fish habitat.

Rick

I also did it with some specialty brackets I made for a surveying project, mounting a water velocity reading meter on the surveyor's prism rod for recording locations of water velocity readings as input to a digital elevation model as part of 3D hydraulic modeling of fish habitat.

Rick

Attachments

-

Acid_Bath_n_Charger.jpg84.1 KB · Views: 21

Acid_Bath_n_Charger.jpg84.1 KB · Views: 21 -

BldrVelos.jpg101.7 KB · Views: 23

BldrVelos.jpg101.7 KB · Views: 23 -

DualPrismBracketOnTopSetRod.jpg32.4 KB · Views: 20

DualPrismBracketOnTopSetRod.jpg32.4 KB · Views: 20 -

Product.jpg65.5 KB · Views: 20

Product.jpg65.5 KB · Views: 20 -

Assembly_1.JPG33.3 KB · Views: 19

Assembly_1.JPG33.3 KB · Views: 19 -

8Holders.JPG55.8 KB · Views: 18

8Holders.JPG55.8 KB · Views: 18 -

QCTP_1.JPG27.2 KB · Views: 20

QCTP_1.JPG27.2 KB · Views: 20 -

Setup.JPG34.2 KB · Views: 19

Setup.JPG34.2 KB · Views: 19 -

IceBathSetup.JPG51.1 KB · Views: 20

IceBathSetup.JPG51.1 KB · Views: 20

Last edited:

I read a bit about it, but it mentioned the parts need to be sand blasted. Not only do I not have any blasting equipment, but I would like the finish to be more or less a mirror.Cerakote can be laser etched

I considered that. How much does it cost? Can the acid be reused?Anodizing can be done in your shop/at home. Pretty simple to do, just takes some water bath containers (ice bath & acid bath), car battery charger, battery (sulfuric) acid, lead probe and misc.

- Joined

- Dec 10, 2023

- Messages

- 77

Sorry, its been over 20 yrs. As I recall, I bought concentrated acid in a small container, which was not at all expensive. Diluted it for the anodizing acid bath. I used the same bath for the series of parts I did for the QCTP, but did not try to save it afterward. The acid is cheap, I wouldn't try to reuse it much at the risk of not doing a good job with the anodizing. The brackets were done a good bit of time different, so ran a new batch. The unused acid concentrate sat in my garage for years after. The lead came from a fishing store and could be the more spendy item these days. The ice bath was one of those clamshell tote boxes and the acid bath was a common plastic bucket. If you don't have a car battery charger, that could be the most expensive item to buy.I considered that. How much does it cost? Can the acid be reused?

I think you should do some internet searching on the process. Get some current (pun not intended) information. There are likely lots of videos out there that weren't when I did it, but I would find a written article or two, for a more definite description and details. It isn't a fast process, so plan ahead for enough time. One of the times I did it was at a family gathering. Leisurely process.

Attachments

The acid can be used many times. I use battery acid (sulfuric acid) and further dilute it. You'll want some aquarium aerators to keep the fluid circulating, both in the electrolyte bath and later, in the dye bath.

Caswell is a good source of dye. (And maybe information.)

You can anodize a polished surface and it will be shinier than a blasted surface, but anodizing will itself dull the surface a little bit.

Many modern battery chargers are too 'smart' for anodizing purposed, but an older unit can be used. I use a lab power supply - eBay or they have some pretty cheap ones on Amazon these days. I anodize at 12A / sqft for 1 hour, so take a look at your parts and let that guide what size power supply you'll need. You can scale it linearly: e.g. 6A/sqft for 2 hours will also work.

GsT

Caswell is a good source of dye. (And maybe information.)

You can anodize a polished surface and it will be shinier than a blasted surface, but anodizing will itself dull the surface a little bit.

Many modern battery chargers are too 'smart' for anodizing purposed, but an older unit can be used. I use a lab power supply - eBay or they have some pretty cheap ones on Amazon these days. I anodize at 12A / sqft for 1 hour, so take a look at your parts and let that guide what size power supply you'll need. You can scale it linearly: e.g. 6A/sqft for 2 hours will also work.

GsT