- Joined

- Apr 1, 2013

- Messages

- 1,142

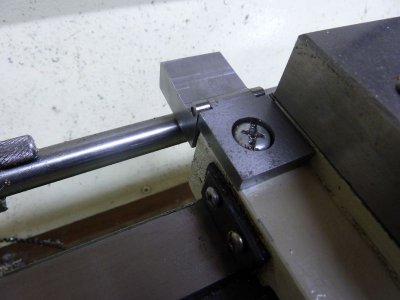

Pretty darn good going to the headstock, But it seems like you are losing something coming back. But it most likely is something seating in or a bur wearing of. Just that .006 in the last 2 runs would make me keep an eye out. Not A lot and on the back swing. I doubt it will be a big deal. Really nice job. can't wait for the video!

Mark

Mark

![IMG_1119[1].JPG IMG_1119[1].JPG](https://www.hobby-machinist.com/data/attachments/56/56865-e20f81b8d5f5a5efe7b7cc00dbff4002.jpg)

![IMG_1121[1].JPG IMG_1121[1].JPG](https://www.hobby-machinist.com/data/attachments/56/56866-b68fd54db71ee7181a916384894af324.jpg)

![IMG_1120[1].JPG IMG_1120[1].JPG](https://www.hobby-machinist.com/data/attachments/56/56867-98d560c59d67eecfab84810e47a013f1.jpg)