- Joined

- Dec 10, 2020

- Messages

- 7

It seems another grimy old machine followed me home about week and a half ago, this time it was a Index 40H, circa 1947. (My serial number is 40H3080, which seems to put the “H” in a different spot that the others I’ve seen). I took everything apart, gave it a thorough cleaning, lube, and adjustment. It seems to be overall decent shape.

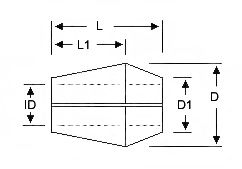

Except...the saddle gib is broken in half. I can still get it to tighten up and still move surprisingly smoothly, but I’m thinking job 1 will be to make a new one and scrape it in, which will be something new for me. I called wells-index and had to get him to pull the prints for it to convince him it wasn’t a tapered gib. he said he’d never seen one like that. But I got the dimensions for

Issue #2, the old double taper collet holder is very, very stuck in the spindle. I’ve tried just about every trick in the book to get it out, and even made up a few tricks of my own, but it seems to run true, so I’m just about at the point where I’m going to give in and get some collets for it and go with that (all it can with was a 5/8). Those collets seem to work for the Tree mill folks. Though I’m open to suggestions.

(non) issue #3- a couple of the pulleys are broken, but it’s going to get a vfd, so I don’t think I’ll need them.

4) it’s missing the power feeds, but I’ll survive

still a lot of nice flaking on the table.

That’s bad

the obligatory trailer shot.

finally got it moved into place today. I think it makes a lovely compliment to my 1944 Logan 200, don’t you agree?

Except...the saddle gib is broken in half. I can still get it to tighten up and still move surprisingly smoothly, but I’m thinking job 1 will be to make a new one and scrape it in, which will be something new for me. I called wells-index and had to get him to pull the prints for it to convince him it wasn’t a tapered gib. he said he’d never seen one like that. But I got the dimensions for

Issue #2, the old double taper collet holder is very, very stuck in the spindle. I’ve tried just about every trick in the book to get it out, and even made up a few tricks of my own, but it seems to run true, so I’m just about at the point where I’m going to give in and get some collets for it and go with that (all it can with was a 5/8). Those collets seem to work for the Tree mill folks. Though I’m open to suggestions.

(non) issue #3- a couple of the pulleys are broken, but it’s going to get a vfd, so I don’t think I’ll need them.

4) it’s missing the power feeds, but I’ll survive

still a lot of nice flaking on the table.

That’s bad

the obligatory trailer shot.

finally got it moved into place today. I think it makes a lovely compliment to my 1944 Logan 200, don’t you agree?