- Joined

- Dec 3, 2020

- Messages

- 159

On my RF-30 clone, the bolts that tighten the head onto the column are a minor pain every time I have to change the head height. I can live with it, but I saw a clever way to tighten them both at once, by welding sprockets to the nuts and connecting them with a chain. Anyone else remember seeing that? I'm 98% sure it was a youtube.

I'm sure you've noticed, if you type "RF-30" or "Rong Fu" or "Round column mill" in Youtube you get dozens of videos, some of them of extremely poor quality, but a few gems. I was trying to find the one with the sprockets and chain for tightening the head bolts, but I seem to be only finding the bad ones where the guy never figured out that you can edit a video.

I'm thinking of trying it (the mill mod, not the video editing!) I'm sure I can work out the details myself, but if someone else has done it first, sometimes you can learn from it. If nothing else, they show you how NOT to do it.

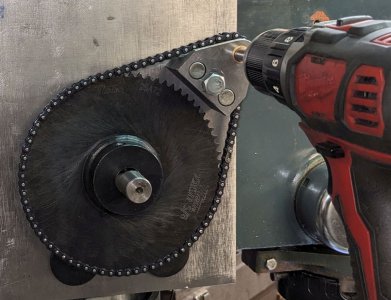

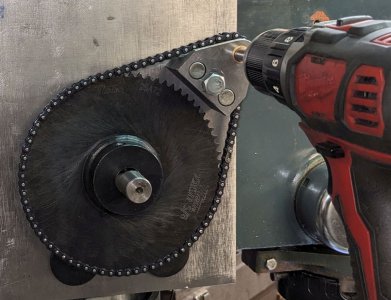

I'm thinking three sprockets, with the third one in front of the back two. I'll power the third one with my cordless drill, with a gear reduction of 4:1 or more, smaller sprocket on the drill, bigger on the nuts, so it gets good and tight without too much force needed by my wimpy arm muscles.

It'd be awesome if someone here has done it, so I can benefit from your actual real-life experience, but I'll settle for speculation and crazy theories. Feel free to tell me if you think it's a dumb idea — save me from myself?

You may have seen my power Z-lift in the other thread, inspired by a couple youtubers (not my invention), works great! So I feel like I'm a whiz with chains and sprockets now, so I want to put them everywhere.

Thanks,

Mark in Seattle

I'm sure you've noticed, if you type "RF-30" or "Rong Fu" or "Round column mill" in Youtube you get dozens of videos, some of them of extremely poor quality, but a few gems. I was trying to find the one with the sprockets and chain for tightening the head bolts, but I seem to be only finding the bad ones where the guy never figured out that you can edit a video.

I'm thinking of trying it (the mill mod, not the video editing!) I'm sure I can work out the details myself, but if someone else has done it first, sometimes you can learn from it. If nothing else, they show you how NOT to do it.

I'm thinking three sprockets, with the third one in front of the back two. I'll power the third one with my cordless drill, with a gear reduction of 4:1 or more, smaller sprocket on the drill, bigger on the nuts, so it gets good and tight without too much force needed by my wimpy arm muscles.

It'd be awesome if someone here has done it, so I can benefit from your actual real-life experience, but I'll settle for speculation and crazy theories. Feel free to tell me if you think it's a dumb idea — save me from myself?

You may have seen my power Z-lift in the other thread, inspired by a couple youtubers (not my invention), works great! So I feel like I'm a whiz with chains and sprockets now, so I want to put them everywhere.

Thanks,

Mark in Seattle