- Joined

- Apr 6, 2011

- Messages

- 2,082

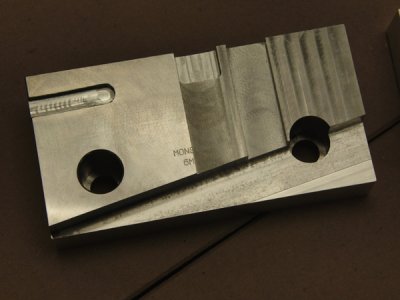

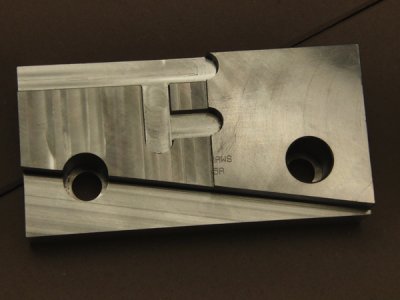

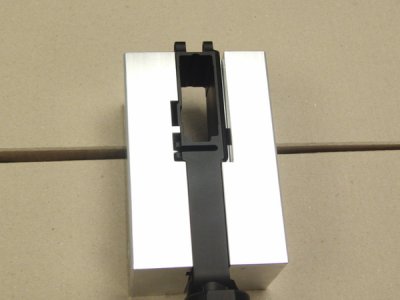

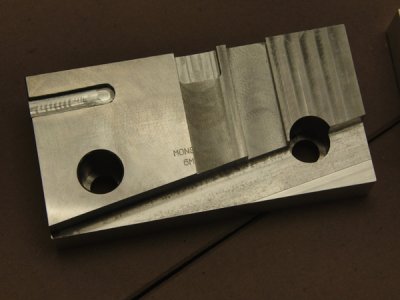

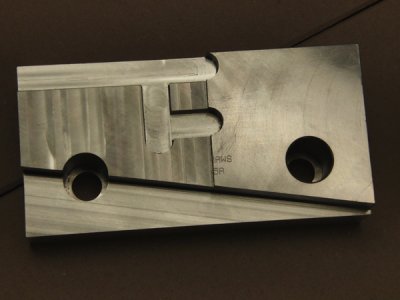

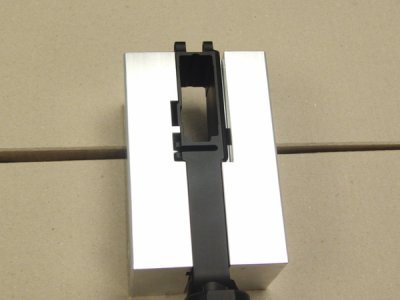

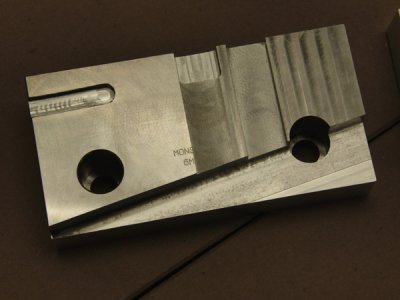

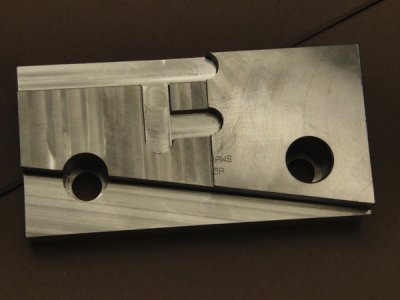

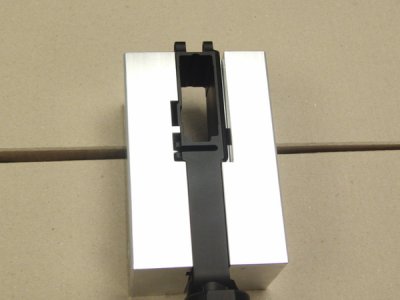

I am planning on making a couple of ARs for myself from 80% finished castings. I just finished making some vise jaws for my Kurt using Ray Brandes' drawings - http://www.lecreg.com/P4x4/ARblank.pdf

I"m sure that I'm over thinking this but now that I'm ready to drill some holes and mill out the receiver I'm looking for the "most accurate" or the "least error prone" way to do it. The way I see it I have three options for how to proceed.

One, fixture the receiver on it's side, locate the holes, drill all the way through and out the opposite side of the casting, then mill out the hammer and trigger cavity.

With this method, I know that drills can drift somewhat and the sides of the casting might not be perfectly parallel anyway. Holes on each side might not "match up" to where they should be.

Two, mill out the hammer and trigger cavity, fixture the receiver on it's side, locate the holes, and drill all the way through the casting out the other side.

This method has the same "problems" as the first but you are drilling through less material (less chance of deflection?) but when the drill hits the other side there is no pilot hole or punch mark and therefore a chance for the drill bit to "walk"?

Three, mill out the hammer and trigger cavity, fixture the receiver on it's side, locate the holes, drill out only that one side, flip the receiver over, re-indicate the holes, and drill the second side out.

The final method drills through less material, as "#2", but alleviates the chance of the drill "walking" as a spot drill can be used on both sides. Where this one is prone to error is simply in the indicating of the holes on both sides and how repeatable those measurements are.

All of the methods look to me to have both "pros" and "cons" but what I'm trying to find out is which "order of operations" would be the least prone to error and why.

Hopefully my explanation is adequate as to what I'm doing/looking for, so now I'd like to hear your thoughts.

Thanks,

-Ron

I"m sure that I'm over thinking this but now that I'm ready to drill some holes and mill out the receiver I'm looking for the "most accurate" or the "least error prone" way to do it. The way I see it I have three options for how to proceed.

One, fixture the receiver on it's side, locate the holes, drill all the way through and out the opposite side of the casting, then mill out the hammer and trigger cavity.

With this method, I know that drills can drift somewhat and the sides of the casting might not be perfectly parallel anyway. Holes on each side might not "match up" to where they should be.

Two, mill out the hammer and trigger cavity, fixture the receiver on it's side, locate the holes, and drill all the way through the casting out the other side.

This method has the same "problems" as the first but you are drilling through less material (less chance of deflection?) but when the drill hits the other side there is no pilot hole or punch mark and therefore a chance for the drill bit to "walk"?

Three, mill out the hammer and trigger cavity, fixture the receiver on it's side, locate the holes, drill out only that one side, flip the receiver over, re-indicate the holes, and drill the second side out.

The final method drills through less material, as "#2", but alleviates the chance of the drill "walking" as a spot drill can be used on both sides. Where this one is prone to error is simply in the indicating of the holes on both sides and how repeatable those measurements are.

All of the methods look to me to have both "pros" and "cons" but what I'm trying to find out is which "order of operations" would be the least prone to error and why.

Hopefully my explanation is adequate as to what I'm doing/looking for, so now I'd like to hear your thoughts.

Thanks,

-Ron