- Joined

- Sep 28, 2013

- Messages

- 4,306

thought I'd made one thread to put all my different mods and futzings around in one place.

The carriage on my 618 has way wipers which work really well, but makes it hard to oil under the carriage, so I added a GITS oiler to each side and used a dremel with a ball end burr to cut oil grooves on the underside. Works a treat, but no pictures - I'll take some when I have the carriage off to adjust the shims.

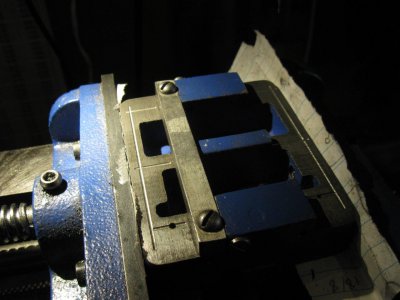

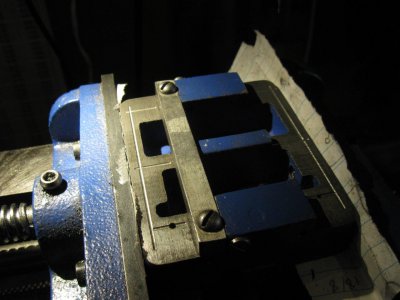

Having oilers and wipers on my carriage made me also want them on my tail stock, so I finished off that project today. Made the wiper holders from some sheet alu (some kind of old filter holder?) and used some of the kids felt and neoprene for the wipers. Cross drilled a 1/8in passage across the base of the tail stock and then drilled oil holes into it from underneath - amazingly the ~3in passage drilled straight and both the oil holes hit it Milled oil grooves with a 1/16 (I think) carbide ball end mill, flushed out the chips and put it all back together again. Works a treat - it's set up tight but slides smoothly.

Milled oil grooves with a 1/16 (I think) carbide ball end mill, flushed out the chips and put it all back together again. Works a treat - it's set up tight but slides smoothly.

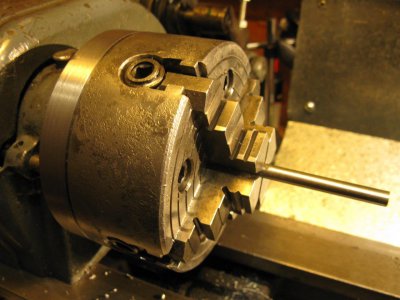

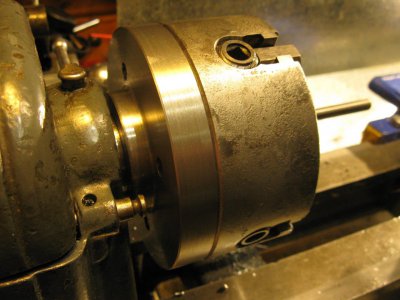

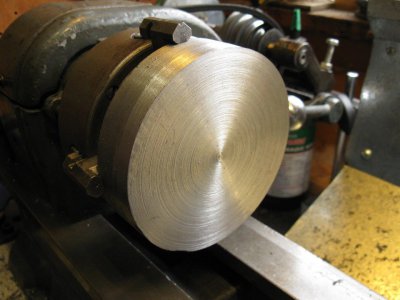

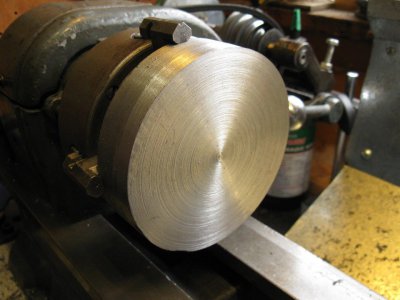

Also working on a back plate for a 4 jaw I got off eBay recently

some very hefty 26mm thick scrap

blank cut out with an angle grinder and a hacksaw

turning down one side - lots of light cuts due to the slightly precarious hold and the interrupted cuts. The treadmill motor worked great down at 50rpm in back gear

turned around, indicated in to ~0.001 and the last bit turned off. Rough faced it to get under the skin of some kind of crazy hard surface treatment - it kept knocking the tip off my HSS bit, so I ended up using a brazed carbide bit which did the trick

have to make a spindle blank and an internal threading bar before proceeding. Oh and learn to thread too

The carriage on my 618 has way wipers which work really well, but makes it hard to oil under the carriage, so I added a GITS oiler to each side and used a dremel with a ball end burr to cut oil grooves on the underside. Works a treat, but no pictures - I'll take some when I have the carriage off to adjust the shims.

Having oilers and wipers on my carriage made me also want them on my tail stock, so I finished off that project today. Made the wiper holders from some sheet alu (some kind of old filter holder?) and used some of the kids felt and neoprene for the wipers. Cross drilled a 1/8in passage across the base of the tail stock and then drilled oil holes into it from underneath - amazingly the ~3in passage drilled straight and both the oil holes hit it

Also working on a back plate for a 4 jaw I got off eBay recently

some very hefty 26mm thick scrap

blank cut out with an angle grinder and a hacksaw

turning down one side - lots of light cuts due to the slightly precarious hold and the interrupted cuts. The treadmill motor worked great down at 50rpm in back gear

turned around, indicated in to ~0.001 and the last bit turned off. Rough faced it to get under the skin of some kind of crazy hard surface treatment - it kept knocking the tip off my HSS bit, so I ended up using a brazed carbide bit which did the trick

have to make a spindle blank and an internal threading bar before proceeding. Oh and learn to thread too