- Joined

- Sep 28, 2013

- Messages

- 4,392

winegrower's thread about arbor spacers reminded me about how I tackled this problem on my grinder and another member suggested I post up the solution as these things tend to fade out of the collective consciousness over time.

Anyway, I had read about autobalancing washing machine drums and Nascar wheels, where they have a sealed groove near the periphery partially filled with steel balls. As the drum or wheel spins up, the balls distribute themselves based on the center of mass (I think) of the wheel until the center of mass is at the center of rotation = perfectly balanced. That sounded like a neat idea, so I gave it a go (plus the stock washers/ arbor spacers were crap).

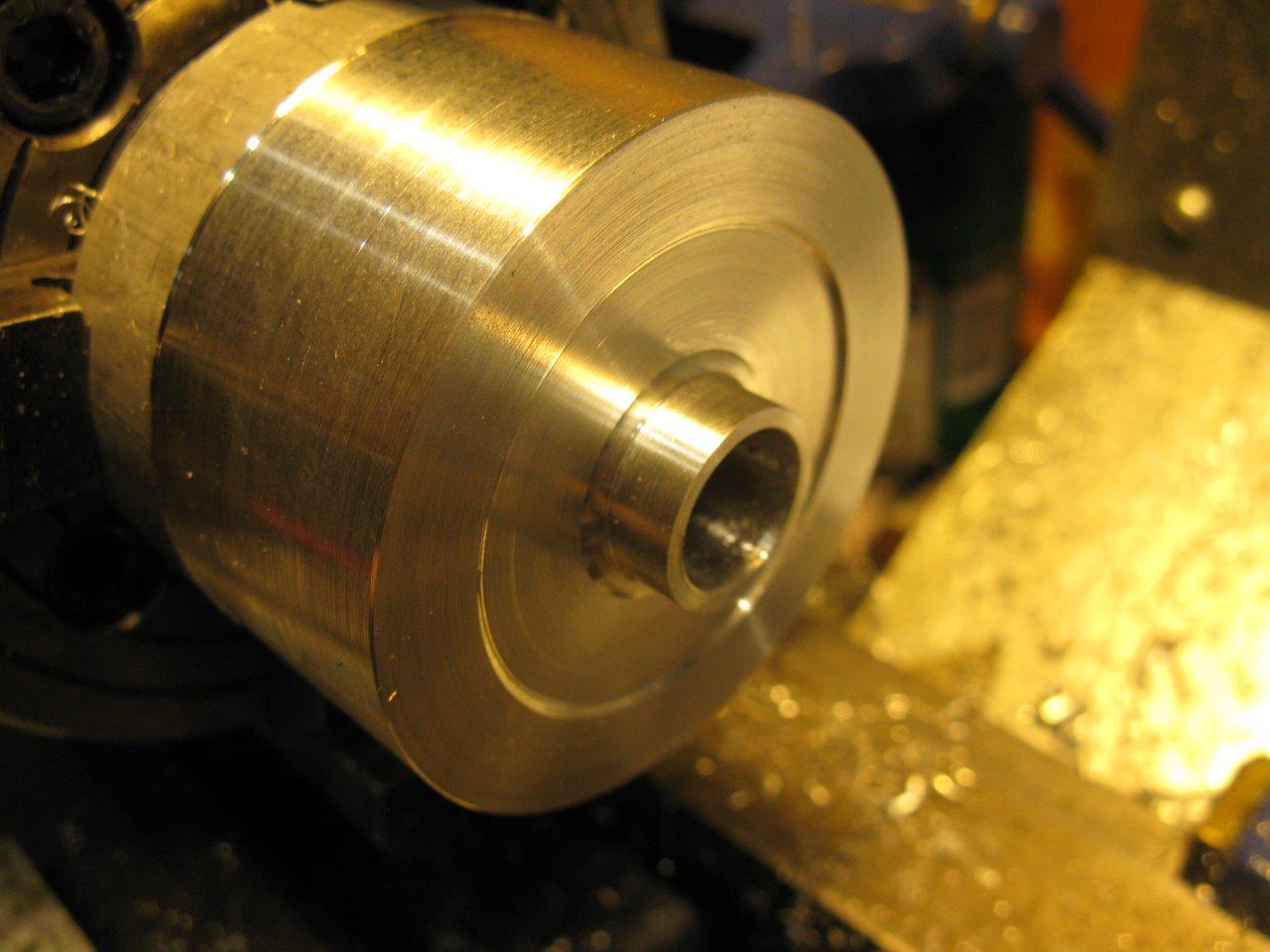

I made these on my Atlas 618 out of alu. First are the i

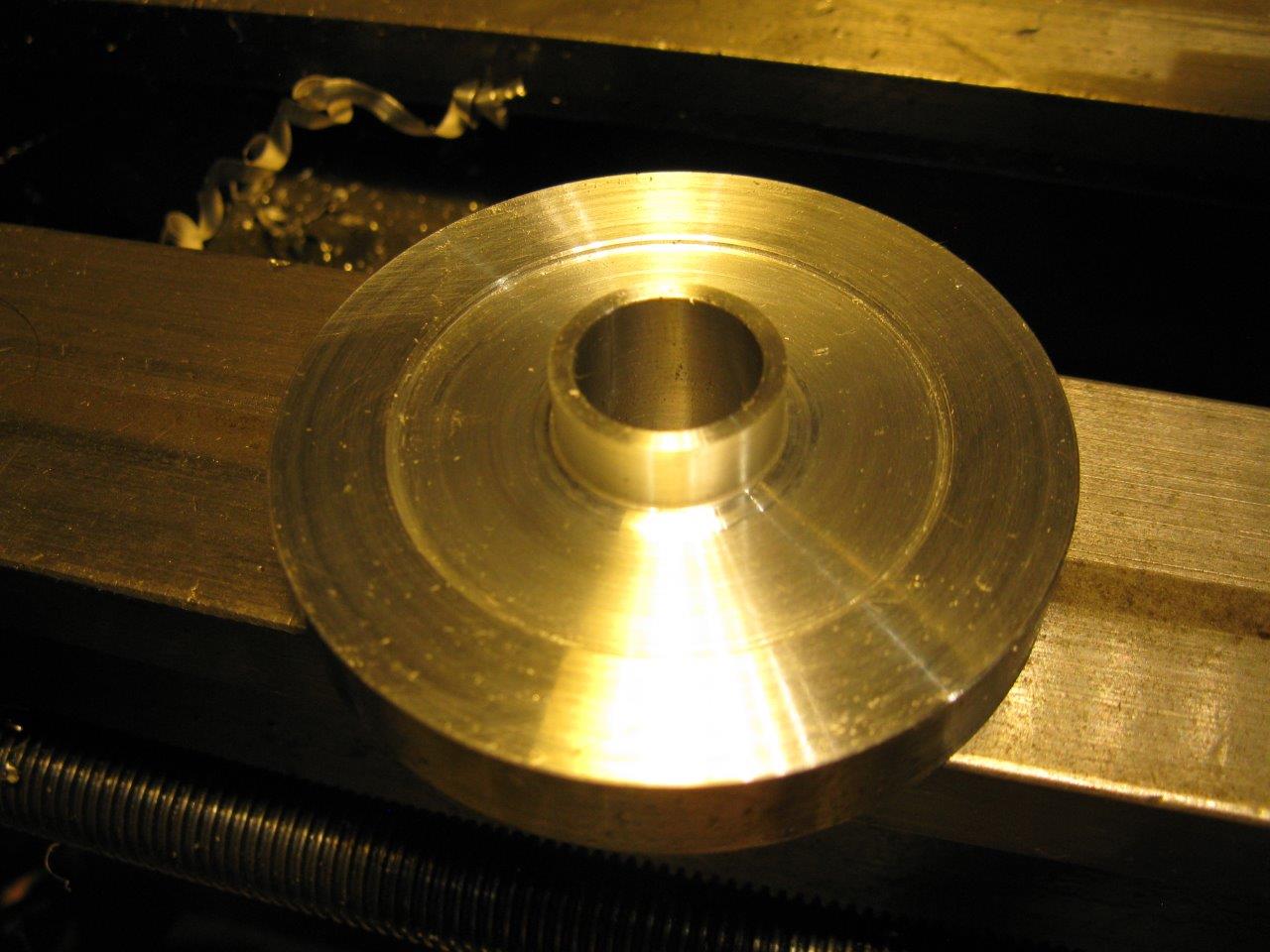

this is one pair - the thin one is the part that goes on the spindle first, then the wheel, then the one on the right goes on after.

Anyway, I had read about autobalancing washing machine drums and Nascar wheels, where they have a sealed groove near the periphery partially filled with steel balls. As the drum or wheel spins up, the balls distribute themselves based on the center of mass (I think) of the wheel until the center of mass is at the center of rotation = perfectly balanced. That sounded like a neat idea, so I gave it a go (plus the stock washers/ arbor spacers were crap).

I made these on my Atlas 618 out of alu. First are the i

this is one pair - the thin one is the part that goes on the spindle first, then the wheel, then the one on the right goes on after.