As some here know, I repair and restore vintage fountain pens, often using my Logan 820 for fabrication and stabilization.

My current challenge is this: A late 1940s-1950s Italian fountain pen, the Aurora 88, was incredibly popular during its long run, and it basically helped restart the Italian commodities market after WWII. Like many Italian pens of the era, it is filled with a relatively piston system. The piston is hollow, activated by a threaded brass rod from the top of the pen; at the piston's business end is a small threaded protuberance upon which gaskets and a small cork are fit (and provide the seal to bring in ink and keep it in) and which are held in place by a nut. The most frequent problem seen in these pens is the disintegration of the threaded protuberance and the nut, probably by ink corrosion. The dimensions of the shaft protuberance are 4.7mm high x 4.5-5mm across; thread is M5-.8 . The nut is 8.5mm x 4.28 ID, thread .8. , 2.5mm thick. These dimensions vary between pens at the .1mm level but the thread is standard. The rest of the pen and the sizes of the gaskets and cork are not relevant here.

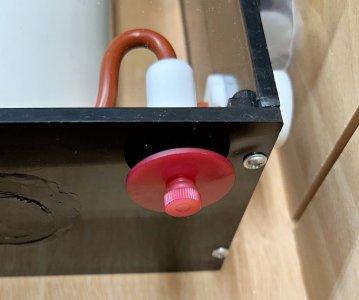

I am trying to develop a means of replacing both threaded shaft and nut. The shaft is easy; note the first picture of a shaft needing repair on top and a healthy one below. Not wanting to attempt very small metric single point threading on my Logan (and I love single point threading...), I have purchased a length of nylon threaded rod OD 4.7mm with M.8 threading, will cut that to fit the length I need plus enough to epoxy into the piston base, after I part the remainder off and either drill or drill and tap. The nut (one is on the ruler) is the challenge: no nut appears to be available on the market that fits the specs. So, I purchased a dozen 5mmx 0.8mm x 8mm nylon pan head machine screws and am thinking of turning and facing them down to size and slicing off the nuts, then stacking them and gang-tapping them. Is this the best way around this challenge? What would you recommend?

By the way, doing this whole job in metric is not mandatory, but I do have some extant threaded nuts and some shafts without nuts so would prefer to be consistent. The only added challenge with metric is my inability to thread them on the Logan.

Also, I"m using nylon because it's impervious to ink, at least for the next 25 years or so. I could also use delrin but don't know if that would be easier or harder to turn at this thickness.

Many thanks!

Tim

My current challenge is this: A late 1940s-1950s Italian fountain pen, the Aurora 88, was incredibly popular during its long run, and it basically helped restart the Italian commodities market after WWII. Like many Italian pens of the era, it is filled with a relatively piston system. The piston is hollow, activated by a threaded brass rod from the top of the pen; at the piston's business end is a small threaded protuberance upon which gaskets and a small cork are fit (and provide the seal to bring in ink and keep it in) and which are held in place by a nut. The most frequent problem seen in these pens is the disintegration of the threaded protuberance and the nut, probably by ink corrosion. The dimensions of the shaft protuberance are 4.7mm high x 4.5-5mm across; thread is M5-.8 . The nut is 8.5mm x 4.28 ID, thread .8. , 2.5mm thick. These dimensions vary between pens at the .1mm level but the thread is standard. The rest of the pen and the sizes of the gaskets and cork are not relevant here.

I am trying to develop a means of replacing both threaded shaft and nut. The shaft is easy; note the first picture of a shaft needing repair on top and a healthy one below. Not wanting to attempt very small metric single point threading on my Logan (and I love single point threading...), I have purchased a length of nylon threaded rod OD 4.7mm with M.8 threading, will cut that to fit the length I need plus enough to epoxy into the piston base, after I part the remainder off and either drill or drill and tap. The nut (one is on the ruler) is the challenge: no nut appears to be available on the market that fits the specs. So, I purchased a dozen 5mmx 0.8mm x 8mm nylon pan head machine screws and am thinking of turning and facing them down to size and slicing off the nuts, then stacking them and gang-tapping them. Is this the best way around this challenge? What would you recommend?

By the way, doing this whole job in metric is not mandatory, but I do have some extant threaded nuts and some shafts without nuts so would prefer to be consistent. The only added challenge with metric is my inability to thread them on the Logan.

Also, I"m using nylon because it's impervious to ink, at least for the next 25 years or so. I could also use delrin but don't know if that would be easier or harder to turn at this thickness.

Many thanks!

Tim

Last edited: