- Joined

- Nov 25, 2015

- Messages

- 8,313

I recently bought a Bosch Glyde CM10GD saw and I need to modify it to improve dust collection, and I tried my old laser that is blade mounted, and as always it sucks. Paid too much for too little.

While searching for dust collection upgrades I came across the addition of the shadow line on the 12" unit. I have the 10" and it looked easy. I did it differently and here's that build. I'll put the dust collection here when I do it, if it works well.

The only machining was mounting the handle to cut out the switch location.

I started with a sewing light. I had one on the mill and decided to sacrifice it for this. One thing I will caution you on if you want to do this, hold the leds up to a light and see if there are any traces that will be lost fitting it to your particular saw. I didn't know that there were traces on the sides, and I sanded through them. I added a jumper to the last led and fixed my problem. Things were tight and I decided to use the trace wire to offer space between the clear plastic to the led board.

I stripped all the parts and wired it directly to the main cord (neutral) and the switch (hot side). I wound up wiring directly to the black entering the switch, not the yellow as may be in the pic.

used double stick tape, attached led and wood. Ran it along belt sander to shape it and create bevel in back to fit into casting. That's the trace (white wire) I had to add back. BTW the wires and solder on the entire sewing light is awful, cold solder joints, and falling off wires. Also the solder would come off the board cleanly, I've never seen that before, usually it stays tinned.. questionable metal/solder.

Sealing up with hot glue (clear plastic ) sealed to board and wood.

Cut out for switch done on milling machine with square file for corner.

The control board, resistors and capacitors.

View attachment 461832

This is where the switch and wiring will go. Not much room to work.

\

\

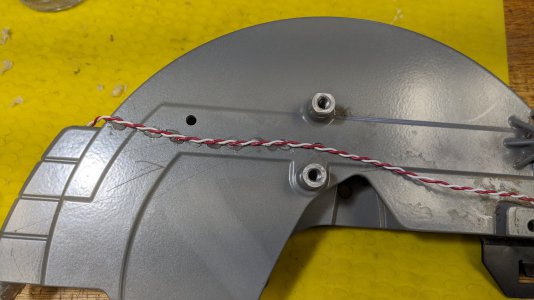

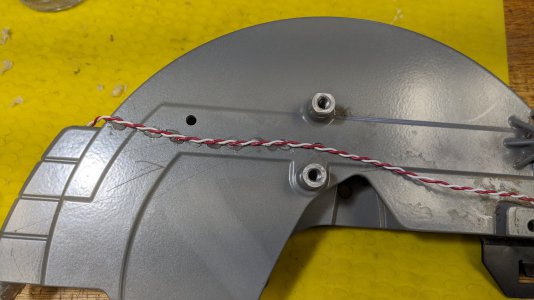

Wiring in place, just need to glue the board in so it doesn't move.

Glued in, and protective plastic patch installed (glued)

Video showing it in use:

While searching for dust collection upgrades I came across the addition of the shadow line on the 12" unit. I have the 10" and it looked easy. I did it differently and here's that build. I'll put the dust collection here when I do it, if it works well.

The only machining was mounting the handle to cut out the switch location.

I started with a sewing light. I had one on the mill and decided to sacrifice it for this. One thing I will caution you on if you want to do this, hold the leds up to a light and see if there are any traces that will be lost fitting it to your particular saw. I didn't know that there were traces on the sides, and I sanded through them. I added a jumper to the last led and fixed my problem. Things were tight and I decided to use the trace wire to offer space between the clear plastic to the led board.

I stripped all the parts and wired it directly to the main cord (neutral) and the switch (hot side). I wound up wiring directly to the black entering the switch, not the yellow as may be in the pic.

used double stick tape, attached led and wood. Ran it along belt sander to shape it and create bevel in back to fit into casting. That's the trace (white wire) I had to add back. BTW the wires and solder on the entire sewing light is awful, cold solder joints, and falling off wires. Also the solder would come off the board cleanly, I've never seen that before, usually it stays tinned.. questionable metal/solder.

Sealing up with hot glue (clear plastic ) sealed to board and wood.

Cut out for switch done on milling machine with square file for corner.

The control board, resistors and capacitors.

View attachment 461832

This is where the switch and wiring will go. Not much room to work.

\

\Wiring in place, just need to glue the board in so it doesn't move.

Glued in, and protective plastic patch installed (glued)

Video showing it in use: