- Joined

- Sep 18, 2017

- Messages

- 12

Bit of long story, but the condensed version is I picked up my Dad's VN 12 that has sat idle with a burned up motor for 25+ years. Disassembled it to the basic components to move from Oklahoma to Texas, cleaned it up, then painted it while torn down. I replaced the burned up motor with a 2HP Rockwell 3 phase motor, and installed a Dayton variable speed motor on the table feed. Lubed everything, and probably my biggest mistake was not removing the cutter head to give it a thorough cleaning......

I started up the mill and everything sounded good, ran it for a while with no load. I then stared machining some table stops, because the machine had none on it, and I heard a bad crunch sound followed by a low frequency thunk thunk thunk sound coming from what sounded like the spindle area. I pulled the drive motor belts off, and rotated the drive side by hand and you could feel a tight spot and a skip when rotating it. I removed the cutter head, and first thing I see is a very nasty looking pinion gear, and inspection of what I could see of the ring gear was a LOT of broken and chipped teeth. Crap....

I cleaned the cutter head with solvent and what I saw really broke my heart. Lodged in old grease were portions of 3 broken teeth, some smaller bits of munched metal, and some ground/pulverized metal bits. The mill had been used for many years in the Horizontal position with an arbor, and I was using it vertically when the **** storm hit. It appears that someone has been into this head at one point, as the number of missing teeth far outnumber the 3 I found, and there really was not much debris in the grease. I see obvious tool marks on parts inside of the cutter head, and likely someone else had seen some damage, cleaned it up, saw missing teeth, reassembled, and ran it like it was. I finished it off, and I guess that a broken tooth dislodged from grease from old spindle bearings, floated in the oil, and landed in my ring or pinion and wreaked havoc.

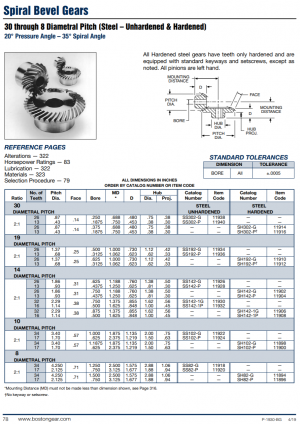

There are a lot of chipped outer edges which I'm not to concerned about, but there is 25-30% of the inside teeth of the ring gear missing on multiple teeth, and a couple that are adjacent, and the pinion is rough. I am sure that VN NOS spares for this machine are rare as hen's teeth. I have used this machine since I was a kid, and really like it, but it is to rough to use as is, and I am sure that there will quickly be more damage if I tried to run it. Please see the attached photos, and the photos actually look better than it is.

What options do I have?

1. Find the unicorn NOS ring and pinion set....

2. Find a used but better condition ring and pinion set for an early VN 12.

3. Have a new ring and pinion made....... probably cost prohibitive.

4. Build up teeth with brass, probably won't hold up, and the heat from brazing will affect the hardness of the ring and pinion, not to mention hand dressing the teeth to an acceptable profile.

5. TIG weld up the missing teeth, and hand dress new teeth, again even more difficulties in hand dressing and heat treatment issues.

Help! I am open to opinions and options. It's a handy machine and I hate to see it sit for another 25 years or be sold for parts.

I started up the mill and everything sounded good, ran it for a while with no load. I then stared machining some table stops, because the machine had none on it, and I heard a bad crunch sound followed by a low frequency thunk thunk thunk sound coming from what sounded like the spindle area. I pulled the drive motor belts off, and rotated the drive side by hand and you could feel a tight spot and a skip when rotating it. I removed the cutter head, and first thing I see is a very nasty looking pinion gear, and inspection of what I could see of the ring gear was a LOT of broken and chipped teeth. Crap....

I cleaned the cutter head with solvent and what I saw really broke my heart. Lodged in old grease were portions of 3 broken teeth, some smaller bits of munched metal, and some ground/pulverized metal bits. The mill had been used for many years in the Horizontal position with an arbor, and I was using it vertically when the **** storm hit. It appears that someone has been into this head at one point, as the number of missing teeth far outnumber the 3 I found, and there really was not much debris in the grease. I see obvious tool marks on parts inside of the cutter head, and likely someone else had seen some damage, cleaned it up, saw missing teeth, reassembled, and ran it like it was. I finished it off, and I guess that a broken tooth dislodged from grease from old spindle bearings, floated in the oil, and landed in my ring or pinion and wreaked havoc.

There are a lot of chipped outer edges which I'm not to concerned about, but there is 25-30% of the inside teeth of the ring gear missing on multiple teeth, and a couple that are adjacent, and the pinion is rough. I am sure that VN NOS spares for this machine are rare as hen's teeth. I have used this machine since I was a kid, and really like it, but it is to rough to use as is, and I am sure that there will quickly be more damage if I tried to run it. Please see the attached photos, and the photos actually look better than it is.

What options do I have?

1. Find the unicorn NOS ring and pinion set....

2. Find a used but better condition ring and pinion set for an early VN 12.

3. Have a new ring and pinion made....... probably cost prohibitive.

4. Build up teeth with brass, probably won't hold up, and the heat from brazing will affect the hardness of the ring and pinion, not to mention hand dressing the teeth to an acceptable profile.

5. TIG weld up the missing teeth, and hand dress new teeth, again even more difficulties in hand dressing and heat treatment issues.

Help! I am open to opinions and options. It's a handy machine and I hate to see it sit for another 25 years or be sold for parts.

Attachments

-

20191222_134020.jpg1.3 MB · Views: 78

20191222_134020.jpg1.3 MB · Views: 78 -

20200111_152323.jpg1.1 MB · Views: 83

20200111_152323.jpg1.1 MB · Views: 83 -

20200111_152335.jpg1.2 MB · Views: 87

20200111_152335.jpg1.2 MB · Views: 87 -

20200111_152558.jpg3 MB · Views: 89

20200111_152558.jpg3 MB · Views: 89 -

20200111_152844.jpg2.2 MB · Views: 87

20200111_152844.jpg2.2 MB · Views: 87 -

20200111_153024.jpg966.8 KB · Views: 88

20200111_153024.jpg966.8 KB · Views: 88 -

20200111_153056.jpg1.1 MB · Views: 84

20200111_153056.jpg1.1 MB · Views: 84 -

20200112_094149.jpg1.1 MB · Views: 82

20200112_094149.jpg1.1 MB · Views: 82 -

20200111_153430.jpg2.2 MB · Views: 81

20200111_153430.jpg2.2 MB · Views: 81 -

20200111_153446.jpg775.3 KB · Views: 86

20200111_153446.jpg775.3 KB · Views: 86 -

20191222_170112.jpg1.2 MB · Views: 95

20191222_170112.jpg1.2 MB · Views: 95

Last edited:

. Happy Hunting!

. Happy Hunting!