I am not sure if this belongs here, but I thought it would be of general interest. Moderators: If it is inappropriate, please move or delete it.

Newly built typical wooden flat bed truck body and cab manufactured at Tillotson's c. 1949 ready for delivery to the customer. Photo of vehicle parked on Tillotson's Works forecourt.

I apprenticed as a truck cab and body builder at the firm of Oswald Tillotson, Burnley, Lancashire, from (circa) 1947 to 1950. Cabs and Flat Bed Bodies were hand built of wood at that time, the cabs being finished with sheet metal (van and panel truck bodies were just starting to be built using extruded aluminum sections and sheeting). I worked mostly in the cab shop doing framework joining and door making/installing, although I occasionally built flat bed truck bodies (always under the watchful eyes and guidance of senior craftsmen) as did all apprentices, from time to time.

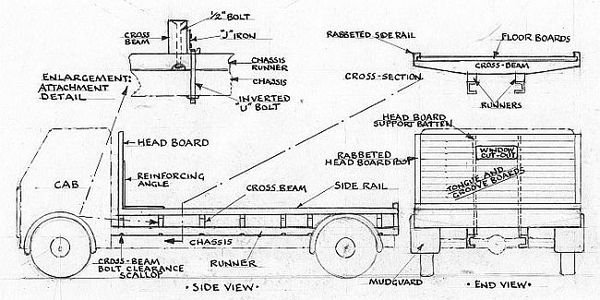

This is a general overview of how wooden flat bed bodies were built at Oswald Tillotson's (and in the trade in general) in the late 1940s -- the materials provided, the methodology employed and the tools used. To that end, I have drawn up a rough sketch of such a truck body.

Informal sketch of a generic Tillotson wooden flat bed truck body produced in the late 1940s. Not to scale or proportion.

I drew it from memory so the scale and proportions are undoubtedly off. Still, I think it is a pretty close approximation.

Unlike building cabs that required refined woodworking skills, flat bed truck bodies were very simple, straightforward and easy to build -- it was more akin to carpentry than fine woodworking (and something like kit building). Because of this, some basic flat bed truck body building was assigned to apprentices who could thereby hone their skills under the watchful eyes of senior craftsmen. Quality of work was the guiding principle. All finished woodwork had to be "triple S" -- Straight, Square & Smooth.

Of course, Customers played a prominent role in determining what specific features and finish their trucks would have. The drawing office would work with them to meet their desires while still adhering to sound construction practices. Some flat bed truck bodies were enhanced by installing detachable side boards and tailgates. Others incorporated custom design features such as abbreviated or contoured head boards. But still the basic flat bed design described here was the most popular one. The more complicated truck body construction was generally reserved for the more seasoned apprentices who also required less supervision.

Job assignment and location

The Shop Foreman assigned jobs to apprentices as they arose. In the case of flat bed body building he would select the job site, issue the appropriate construction drawings and provide the wood "kit" prepared by the Mill shop -- laid out by him and transported to the job site by laborers.

The truck was parked in whatever shop space was available -- sometimes in the cab shop -- as determined by the foreman.

Trucks were in stripped configuration (only engine, transmission and chassis) with a temporarily secured wooden box that had been used as a seat by a company driver to deliver the vehicle from the manufacturer.

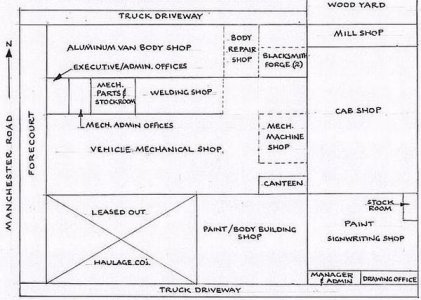

Informal sketch of Tillotson Works layout circa. 1948 - not to scale or proportion

As with the truck body sketch, I drew this from memory, so again the scale and proportions are undoubtedly off (probably more so than with the truck body sketch). By providing this rough drawing I hope to convey a sense of the production environment and the work flow.

I think Tillotson's physical plant was typical of similar British manufacturing businesses of the period. There was no compressed air system in any of the woodworking shops and therefor pneumatic tools were not used. There was overhead electric and natural lighting throughout and electrical outlets were provided in most shops. The Mill Shop had electrically operated machinery: circular saws, band saws, planers, sanders, drilling machines, shapers/routers, etc. There were no individual electrically operated hand-operated tools used such as circular saws, screw drivers, jigsaws, sanders, glue guns, nail guns, routers, etc.

Wood used in building flat bed bodies

To the best of my recollection, and as a general rule, cross-beams and chassis runners were English oak; side rails were ash; floor boards were Jarrah; head board posts and battens were ash; head board tongue and groove was white pine.

The use of (Australian) Jarrah for floor boards was a post-war innovation at Tillotson's -- it was favored because of its toughness, wearability and weather resistance properties. I am not certain that white pine was always used for head board tongue and groove.

Tools and equipment for the job

I used a pretty basic tool kit when building flat beds. Upon being given the assignment, I would usually take my tool box, or a tote containing the tools I anticipated using, to the job site and set up a makeshift work bench using heavy boards on two saw horses.

Equipment: There was always plenty of company owned communal equipment available for anyone's use in all the shops.

Order of Work (to the best of my recollection).

All fabricated wood joints, surfaces and installations were squared, aligned and smoothed throughout the construction process. Iron fittings ("J" and "U" and reinforcement angles) and bolts were sometimes issued from the stockroom -- they were fabricated/modified by the blacksmiths.

The work of Apprentices was continually scrutinized and checked by Craftsmen and the Shop Foreman for quality of worksmanship and appearance. Shortly before completion of construction a craftsman painter would go over all the surfaces to be sure they were sufficiently smooth for painting -- he would point out any deficiencies and require corrective action. The Shop Foreman would perform a final inspection and acceptance of work.

Installation of Cab

At some point toward the completion of the body work the cab -- which had been built elsewhere by a Craftsman assisted by Apprentices -- would be installed, fitted and finished, usually by the same crew that built it.

.........................................

James

Newly built typical wooden flat bed truck body and cab manufactured at Tillotson's c. 1949 ready for delivery to the customer. Photo of vehicle parked on Tillotson's Works forecourt.

I apprenticed as a truck cab and body builder at the firm of Oswald Tillotson, Burnley, Lancashire, from (circa) 1947 to 1950. Cabs and Flat Bed Bodies were hand built of wood at that time, the cabs being finished with sheet metal (van and panel truck bodies were just starting to be built using extruded aluminum sections and sheeting). I worked mostly in the cab shop doing framework joining and door making/installing, although I occasionally built flat bed truck bodies (always under the watchful eyes and guidance of senior craftsmen) as did all apprentices, from time to time.

This is a general overview of how wooden flat bed bodies were built at Oswald Tillotson's (and in the trade in general) in the late 1940s -- the materials provided, the methodology employed and the tools used. To that end, I have drawn up a rough sketch of such a truck body.

Informal sketch of a generic Tillotson wooden flat bed truck body produced in the late 1940s. Not to scale or proportion.

I drew it from memory so the scale and proportions are undoubtedly off. Still, I think it is a pretty close approximation.

Unlike building cabs that required refined woodworking skills, flat bed truck bodies were very simple, straightforward and easy to build -- it was more akin to carpentry than fine woodworking (and something like kit building). Because of this, some basic flat bed truck body building was assigned to apprentices who could thereby hone their skills under the watchful eyes of senior craftsmen. Quality of work was the guiding principle. All finished woodwork had to be "triple S" -- Straight, Square & Smooth.

Of course, Customers played a prominent role in determining what specific features and finish their trucks would have. The drawing office would work with them to meet their desires while still adhering to sound construction practices. Some flat bed truck bodies were enhanced by installing detachable side boards and tailgates. Others incorporated custom design features such as abbreviated or contoured head boards. But still the basic flat bed design described here was the most popular one. The more complicated truck body construction was generally reserved for the more seasoned apprentices who also required less supervision.

Job assignment and location

The Shop Foreman assigned jobs to apprentices as they arose. In the case of flat bed body building he would select the job site, issue the appropriate construction drawings and provide the wood "kit" prepared by the Mill shop -- laid out by him and transported to the job site by laborers.

The truck was parked in whatever shop space was available -- sometimes in the cab shop -- as determined by the foreman.

Trucks were in stripped configuration (only engine, transmission and chassis) with a temporarily secured wooden box that had been used as a seat by a company driver to deliver the vehicle from the manufacturer.

Informal sketch of Tillotson Works layout circa. 1948 - not to scale or proportion

As with the truck body sketch, I drew this from memory, so again the scale and proportions are undoubtedly off (probably more so than with the truck body sketch). By providing this rough drawing I hope to convey a sense of the production environment and the work flow.

I think Tillotson's physical plant was typical of similar British manufacturing businesses of the period. There was no compressed air system in any of the woodworking shops and therefor pneumatic tools were not used. There was overhead electric and natural lighting throughout and electrical outlets were provided in most shops. The Mill Shop had electrically operated machinery: circular saws, band saws, planers, sanders, drilling machines, shapers/routers, etc. There were no individual electrically operated hand-operated tools used such as circular saws, screw drivers, jigsaws, sanders, glue guns, nail guns, routers, etc.

Wood used in building flat bed bodies

To the best of my recollection, and as a general rule, cross-beams and chassis runners were English oak; side rails were ash; floor boards were Jarrah; head board posts and battens were ash; head board tongue and groove was white pine.

The use of (Australian) Jarrah for floor boards was a post-war innovation at Tillotson's -- it was favored because of its toughness, wearability and weather resistance properties. I am not certain that white pine was always used for head board tongue and groove.

Tools and equipment for the job

I used a pretty basic tool kit when building flat beds. Upon being given the assignment, I would usually take my tool box, or a tote containing the tools I anticipated using, to the job site and set up a makeshift work bench using heavy boards on two saw horses.

Rip hand saws and jointer/jack bench planes were not needed as all lumber had been sawn and planed straight and square in the Mill Shop (but not cut to length) and so only smoothing and block planes were needed to dress up joints, etc.

Equipment: There was always plenty of company owned communal equipment available for anyone's use in all the shops.

- Saw benches/horses - Standard shop equipment.

- Glue Pots - Double boiler.

- Sash/bar clamps (cramps - Brit.) - various capacities.

- Squaring sticks - standard shop equipment.

- Body rollers - 6 ft Lengths of 3" diameter heavy pipe.

- Wooden step-stools and folding ladders - standard shop equipment.

Order of Work (to the best of my recollection).

- Position and align chassis runners - after first cleaning the surfaces of chassis longitudinal members - dress/smooth runners and cut to length as needed.

- Position and secure cross-beams to runners - drill out pilot holes using breast drill or bit brace and install ½" bolts, "J" irons and "U" bolts as needed (draw from blacksmith).

- Position and secure side rails to cross-beams - dress/smooth rails and cut to length as needed - fresh out rabbet (Stanley No. 78 plane) as needed - drill out pilot holes using breast drill or bit brace and install bolts (draw from blacksmith).

- Square up structure and install truck bed flooring - carefully install register board - secure remainder of boards - drill countersink pilot holes and snug down each board using greased No. 12 flat head screws (Company issued electric hand drill and/or bit brace).

- Install head board posts - dress/smooth posts and cut to length as needed - fresh out rabbet (Stanley No. 78 plane) as needed - join post to front of chassis runner - drill pilot holes and reinforce using greased No. 12 flat head screws.

- Install head board battens - dress/smooth battens and cut to length as needed - secure using greased No. 12 flat head screws with "YANKEE" quick return spiral ratchet screwdriver.

- Install tongue and groove head boards (cut out opening for cab window) - dress/smooth boards and cut to length as needed - secure using greased No. 12 flat head screws in pilot holes with "YANKEE" quick return spiral ratchet screwdriver.

- Install head board post reinforcing angles - draw from blacksmith - drill out pilot holes using breast drill or bit brace - secure to headboard posts/side rails using bolts.

- Install mud guards - draw from stock room - fabricate brackets and secure to cross-beams using bolts.

- Fabricate and Install special items requested by the customer - Toolboxes, storage boxes, hinged sideboards/tailgates, special reinforcements, etc.

All fabricated wood joints, surfaces and installations were squared, aligned and smoothed throughout the construction process. Iron fittings ("J" and "U" and reinforcement angles) and bolts were sometimes issued from the stockroom -- they were fabricated/modified by the blacksmiths.

InspectionThe work of Apprentices was continually scrutinized and checked by Craftsmen and the Shop Foreman for quality of worksmanship and appearance. Shortly before completion of construction a craftsman painter would go over all the surfaces to be sure they were sufficiently smooth for painting -- he would point out any deficiencies and require corrective action. The Shop Foreman would perform a final inspection and acceptance of work.

Installation of Cab

At some point toward the completion of the body work the cab -- which had been built elsewhere by a Craftsman assisted by Apprentices -- would be installed, fitted and finished, usually by the same crew that built it.

.........................................

James

Last edited by a moderator: