Hi Guys,

I have a Clausing-Colchester Type 8014 square head 13 inch lathe from the late 1960's. (Colchester Master 2500 http://www.lathes.co.uk/colchester/page17.html). And I have been working on fixing the parts that are not functioning properly or are worn more than I want. My most recent effort is to reproduce the pinion shaft that is part of the carriage apron and runs on the rack.

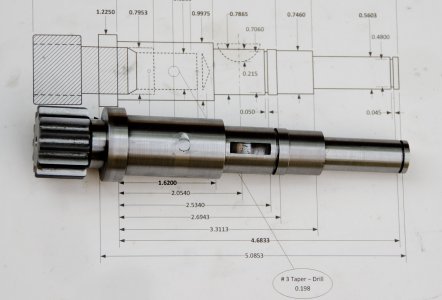

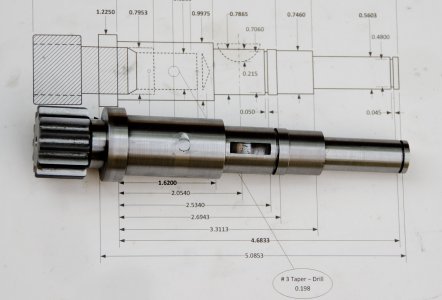

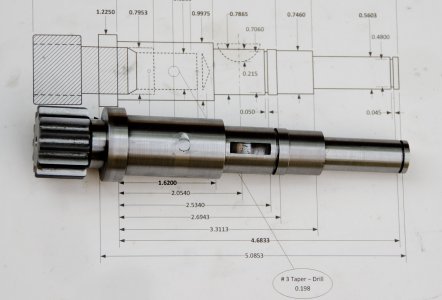

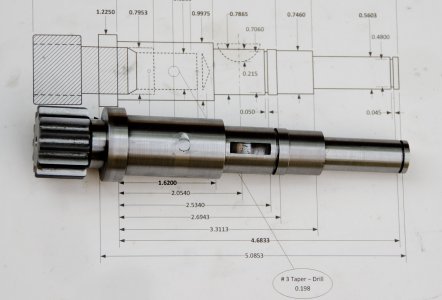

In the pictures you can see the original with the chewed up gear (below and to the right in the first 2 photos) and my replacement (new part above and to the left.) Clausing wanted $1375 or so for this part. On mine the gear bit was purchased from QTC - a division of SDP / Sterling - with induction hardened and ground tooth surfaces - for about $95. (http://www.qtcgears.com/RFQ/default.asp?Page=../KHK/newgears/KHK044.html).

The third photo has my sketch showing how the purchased pinion shaft was turned and pinned in place. I made the collar part a bit wider than the original to have increased mating with the ground reference shaft of the gear. I took the old one out and put my replacement in and after a bit of last minute deburring it all went back together just like it should. And the carriage motion is smoother than it was before. (At least I'm telling myself that...)

All that is prologue to the question I came to ask. How much backlash is appropriate in this gear when mated with the rack? I measure about 0.030 which is more that I thought a well mated gear should have. My goal would be less than 0.005. The factors that contribute to this are the wear in the ways and saddle. plus when I measured the original pinion I had to assume that the tooth profile was offset by roughly 0.012. This profile offset is often used in pinions with fewer than 12 teeth. My replacement part was not produced with this feature. What I might be able to do about this is to move the rack down by 0.040 or so. Is it worth it? I will end up with a series of abandoned screw and alignment dowel holes and the rack will stop too soon -- by about 1 inch on the tailstock end. Not great but not the end of the world either.

My next work item is to get the ways reground. I'm certainly not going to mess with adjusting the rack until I reestablish the turcite leveling of the carriage ways. After that the rack might have to be lowered to deal with the backlash issue. Any thoughts on this?

Paul in Campbell California.

I have a Clausing-Colchester Type 8014 square head 13 inch lathe from the late 1960's. (Colchester Master 2500 http://www.lathes.co.uk/colchester/page17.html). And I have been working on fixing the parts that are not functioning properly or are worn more than I want. My most recent effort is to reproduce the pinion shaft that is part of the carriage apron and runs on the rack.

In the pictures you can see the original with the chewed up gear (below and to the right in the first 2 photos) and my replacement (new part above and to the left.) Clausing wanted $1375 or so for this part. On mine the gear bit was purchased from QTC - a division of SDP / Sterling - with induction hardened and ground tooth surfaces - for about $95. (http://www.qtcgears.com/RFQ/default.asp?Page=../KHK/newgears/KHK044.html).

The third photo has my sketch showing how the purchased pinion shaft was turned and pinned in place. I made the collar part a bit wider than the original to have increased mating with the ground reference shaft of the gear. I took the old one out and put my replacement in and after a bit of last minute deburring it all went back together just like it should. And the carriage motion is smoother than it was before. (At least I'm telling myself that...)

All that is prologue to the question I came to ask. How much backlash is appropriate in this gear when mated with the rack? I measure about 0.030 which is more that I thought a well mated gear should have. My goal would be less than 0.005. The factors that contribute to this are the wear in the ways and saddle. plus when I measured the original pinion I had to assume that the tooth profile was offset by roughly 0.012. This profile offset is often used in pinions with fewer than 12 teeth. My replacement part was not produced with this feature. What I might be able to do about this is to move the rack down by 0.040 or so. Is it worth it? I will end up with a series of abandoned screw and alignment dowel holes and the rack will stop too soon -- by about 1 inch on the tailstock end. Not great but not the end of the world either.

My next work item is to get the ways reground. I'm certainly not going to mess with adjusting the rack until I reestablish the turcite leveling of the carriage ways. After that the rack might have to be lowered to deal with the backlash issue. Any thoughts on this?

Paul in Campbell California.

Last edited: