Well now I've done it. I have a project that will stretch the under quill capacity of my mill and was lowering the knee to see what was possible and apparently ran it off the lifting mechanism. Now the lift crank just free wheels and the knee is stuck at/near the bottom. Didn’t even occur to me it would even be possible. Thought I’d ask for some help on this one so I don’t dork it up.

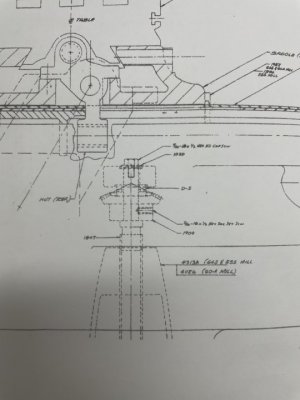

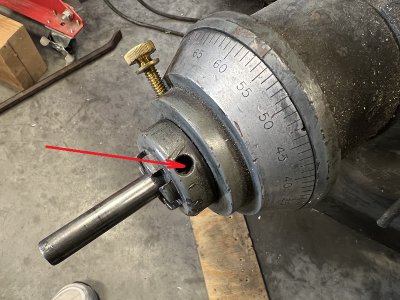

I assume it’s just a jack screw that has somehow disengaged at limit but the drawings in the manuals are so busy I can’t tell. I tried to lift the knee with a jack thinking I’d get enough movement to reengage the screw but even at the point of the machine base lifting, no luck. I might be applying the lifting force too far out on the knee to get movement in the ways. My next move will be to grab my manual fork lift, move the Y Axis on the mill to the rear, and either attach the forks to the surface or under the table clear of the screw and scale.

What am I up against here? Any advice appreciated.

As far as the model, not entirely sure, but we discussed it in this thread and it was suggested it could be a 745 head on 555.

https://www.hobby-machinist.com/threads/what-have-i-got.89454/

Best,

Kelly

I assume it’s just a jack screw that has somehow disengaged at limit but the drawings in the manuals are so busy I can’t tell. I tried to lift the knee with a jack thinking I’d get enough movement to reengage the screw but even at the point of the machine base lifting, no luck. I might be applying the lifting force too far out on the knee to get movement in the ways. My next move will be to grab my manual fork lift, move the Y Axis on the mill to the rear, and either attach the forks to the surface or under the table clear of the screw and scale.

What am I up against here? Any advice appreciated.

As far as the model, not entirely sure, but we discussed it in this thread and it was suggested it could be a 745 head on 555.

https://www.hobby-machinist.com/threads/what-have-i-got.89454/

Best,

Kelly