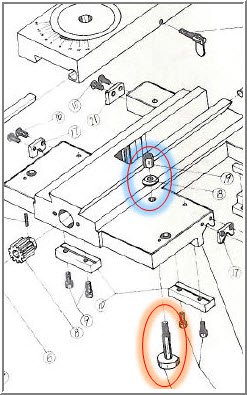

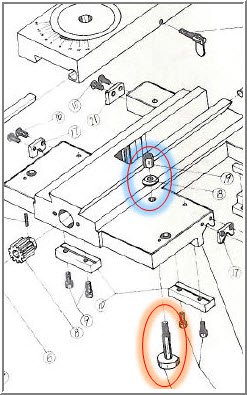

Is the carriage clamping mechanism on your PM lathe similar to this? (my lathe). Was the topside originally a nut? Just curious, my (hex nut) requires a bit of futzing sometimes to get the tightening initiated. Sometimes the lower clamp will just rotate with the tightening motion. Seems like it needs just bit of lateral force on the nut simultaneous to tightening, or if the carriage is displaced just a bit & then it 'engages'. The pic shows it has some sort of eccentric shape on the shoe. I haven't removed it. but suspect the issue is in there somewhere. Bu maybe your handle mod, once set up, limits the clock rotation to a narrower angle to either 'free' or 'clamp'?