Hello,

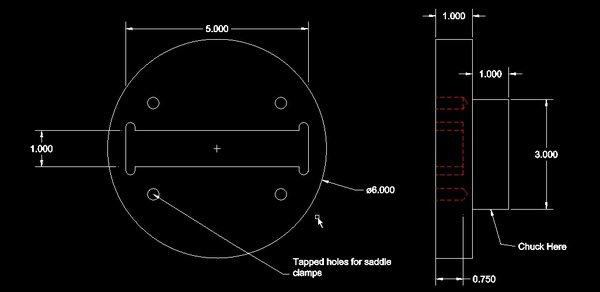

I'd be curious about suggestions on how best to center a rod (about 1" diameter x 5" length) using a 4-jaw chuck in such a way that the rod's axis is perpendicular to the axis of the lathe, and that I can use a tailstock chuck to drill a hole through the diameter of the rod.

I realize that it would be fairly straight-forward to do this on a mill, but I'd like to have a method which I could apply to a lathe.

Thank you!

Hannes.

I'd be curious about suggestions on how best to center a rod (about 1" diameter x 5" length) using a 4-jaw chuck in such a way that the rod's axis is perpendicular to the axis of the lathe, and that I can use a tailstock chuck to drill a hole through the diameter of the rod.

I realize that it would be fairly straight-forward to do this on a mill, but I'd like to have a method which I could apply to a lathe.

Thank you!

Hannes.